Custom linear springs were designed for Longitudinal, Lateral & Angular adjustments and manufactured in plastic and tested in the early stages of prototyping.

Key Engineering Solutions

Solutions

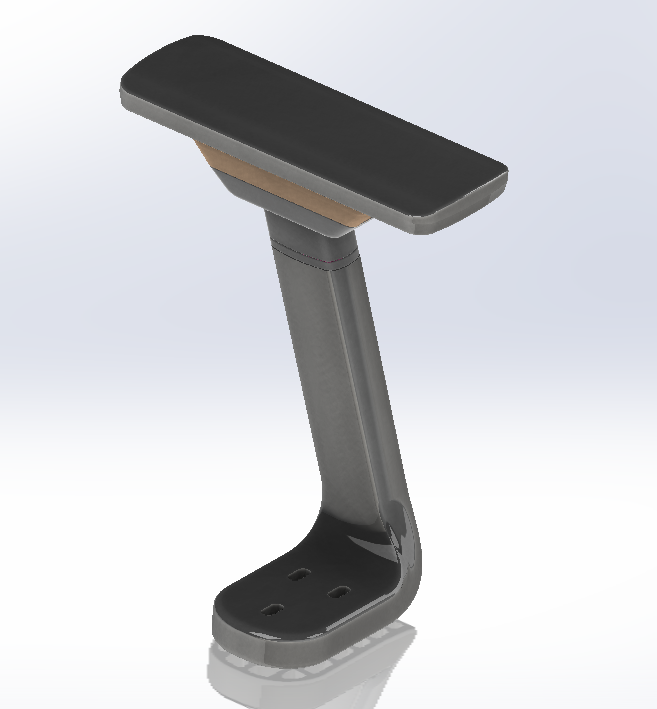

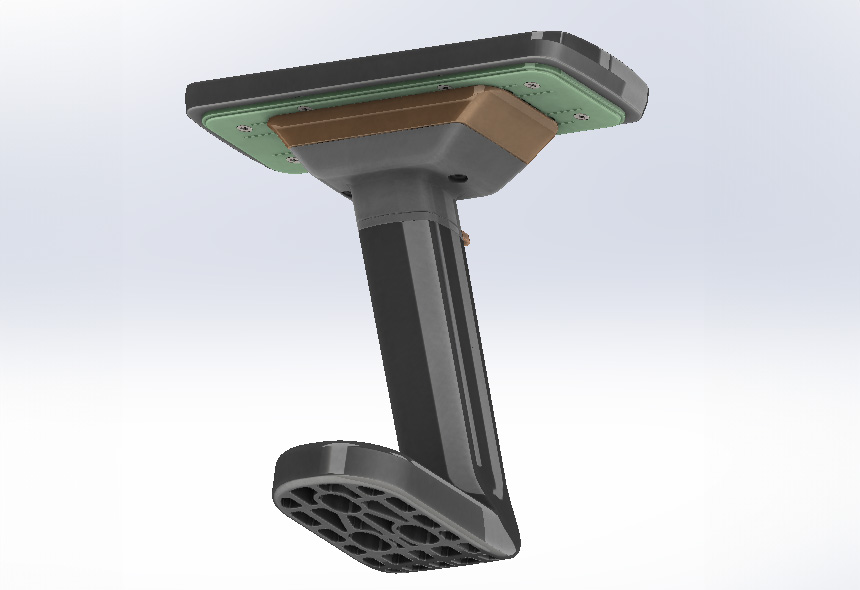

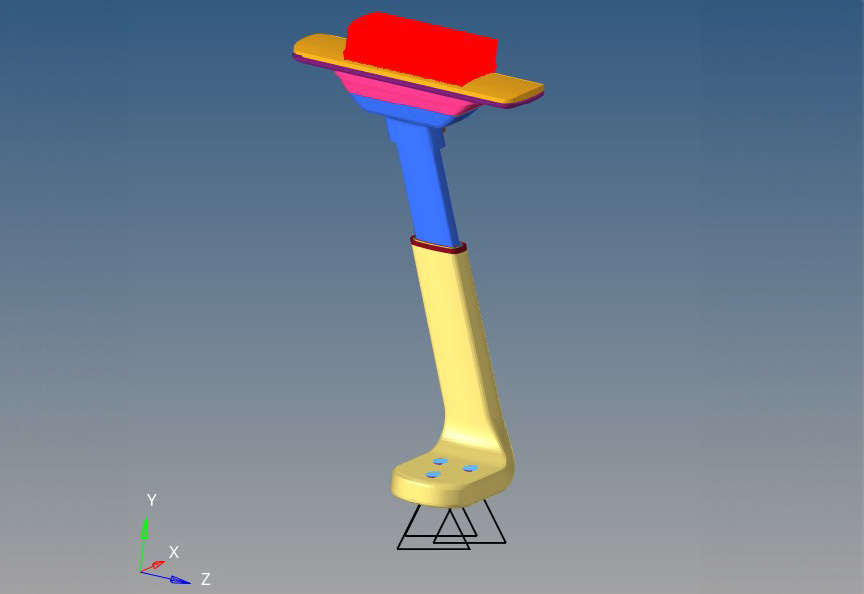

Timetooth initiated the project with preliminary study of multiple designs and benchmarking and tear down of market products. Next preliminary conceptualisation of a 4D armrest design was done. A modular solution was designed including linkages and springs. Custom linear springs were designed for adjustments (Longitudinal, Lateral & Angular) and manufactured in plastic and tested in the early stages of prototyping.

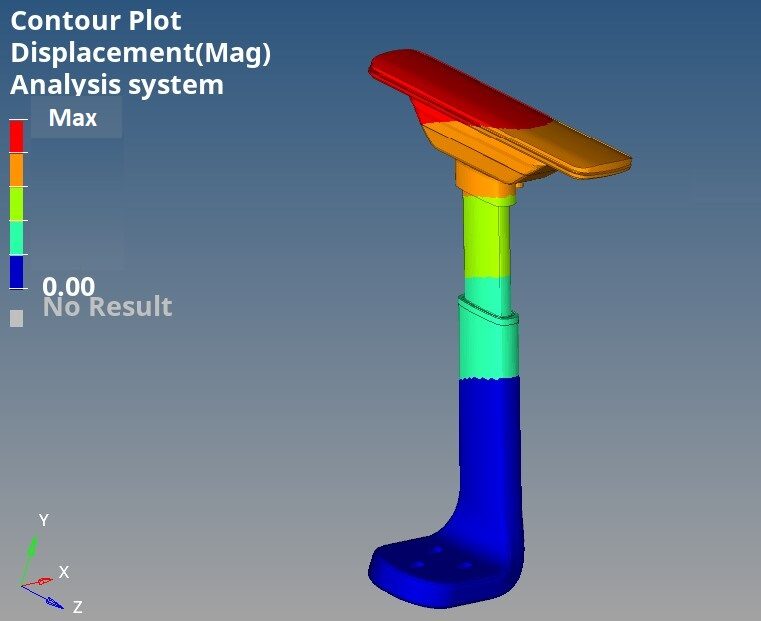

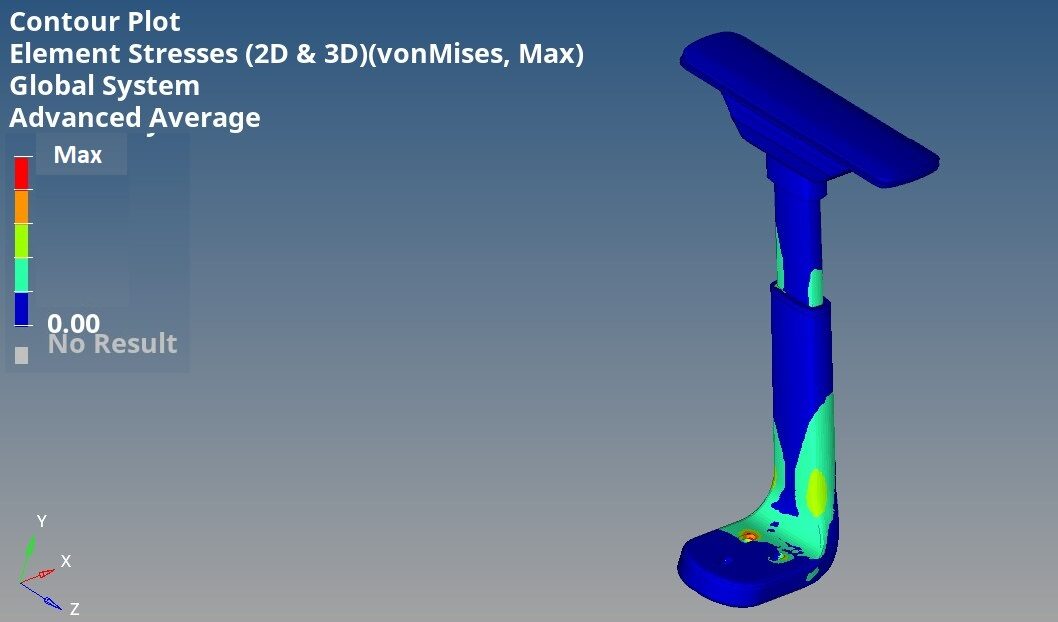

Further design calculations and FEA analysis were performed. The final design was optimized to predict the behavior of the design under stress conditions. Timetooth leveraged virtual simulations for structural rigidity tests to meet the BIFMA X5.1 2017 regulatory standard. The final design was prototyped rapidly to demonstrate functionality and aesthetics. Design was released for manufacturing to the client and simulation results were shared with the client.