Turnkey New Product

Development

A product's journey from ideation to standardized production is challenging. With over a decade of experience, Timetooth swiftly leads an idea to an innovative product providing assistance throughout the product life cycle.

Feasibility

Feasibility study of the idea

During the ideation process, identification of key challenges, development time, size/scale and estimate of costing play an important role. Timetooth initiates the project with systematic feasibility studies of the idea providing valuable insight on viability of the project.

Quantified estimation

As a Timetooth client, you are presented with quantified estimates of costing, timelines, resources required and alternate approaches for journey to market, so that you can make an informed decision. Primary calculations and conceptualisation with study of market benchmarks, technology market, equivalent platforms is done.

Preliminary and Detailed Design

Simulation-driven engineering

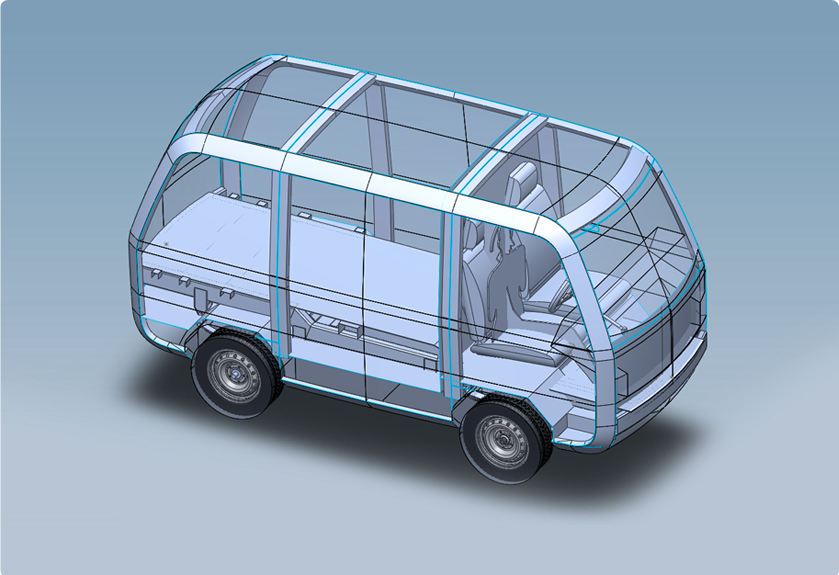

Timetooth uses simulation-driven engineering for designing and developing of products. Virtual engineering helps in fast realization of products and out of box designs. Specialization in simulations offers a great correlation minimizing testing and prototyping costs considerably. The product is evolved through a series of design verification processes and multidisciplinary simulations identifying any gaps in design and resolving them early on.

Design for manufacturing

We follow a phase gate approach in the product development process covering all steps from conceptualisation, preliminary engineering design to detailed design. Detail Design is developed considering manufacturing processes including GD&T, finishing and production volume. Tooling and rapid prototyping balance helps in making decisions regarding sourcing or manufacturing of parts.

Sourcing

Building a supplier ecosystem

Procurement of parts for complex products greatly impacts performance of the product. Timetooth plays a key role in identification of the suppliers using its ecosystem of vendors considering cost targets and lead (time) targets.

Vendor management

We engage early on with the right team as per the specifications and requirements of the project ensuring a product that outperforms best-in-class. We take on administering and managing roles as well.

Regulatory

Conformance to governing standards with focus on quality management

Aerospace, Defence and medical industries are highly regulated for ensuring safety and reliability of the products. Timetooth follows a process driven culture through quality management systems with a decade of experience in regulatory industries. Timetooth documents the design and manufacturing processes conforming to international standards and regulations opening new market segments for the product. Standards require design history, files, manufacturing traceability, quality testing records.

Validation

Hardware testing for product performance

Timetooth at its state of the art testing lab builds custom systems for product specific performance tests. For specific functional tests instrumentation and measurement machines are built in house. Timetooth houses data acquisition equipment and a configurable lab for mechanical and electronic tests. Environmental and characterisation tests are carried out at qualified and accredited test centres.

Limited Production

Prototype and low volume production

Timetooth has expanded its services and offers low volume series production using its manufacturing ecosystem. Timetooth focuses on Good Manufacturing Practices (GMP) regulations for medical devices and International Aerospace Quality Group (IAQG) regulations as per AS9100 standard for defense and aerospace production. Timetooth supports multiple startups in initial production of the products. The manufactured products are OECD market ready.

Installation

On site product installation support

Timetooth’s team assembles and installs the product on site. Our specialised technicians and engineers partners in live trials. Our team provides assistance for smooth transition and handover of product.

Maintenance & Support

Post sales support and service

Timetooth provides post sales support offering AMCs. Maintenance, Support, Repair & Overhaul services for new products developed. Product upgrades are baked in the design and manufacturing plans. Post market monitoring and surveillance for regulatory mandated requirements are provided by the team.