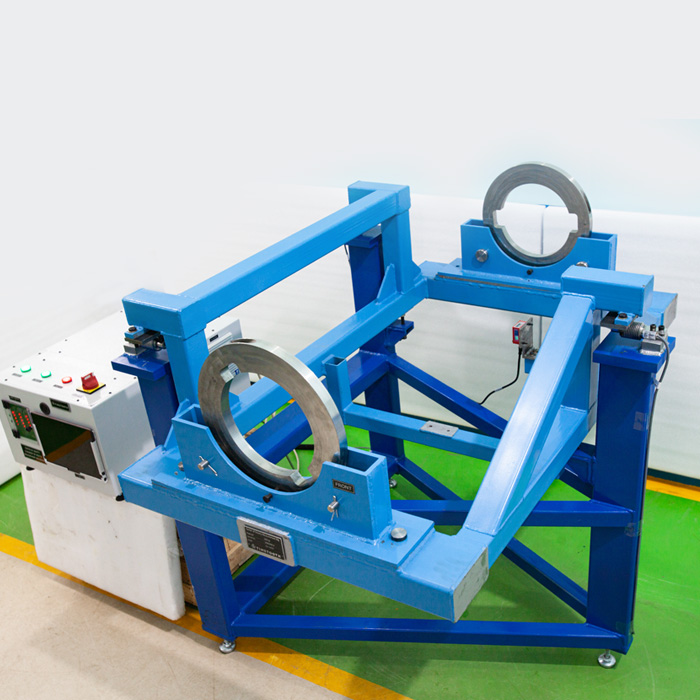

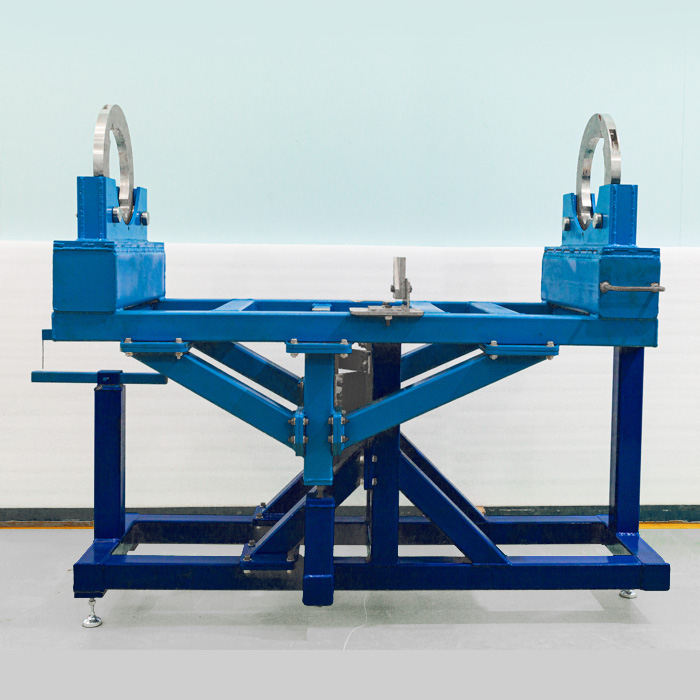

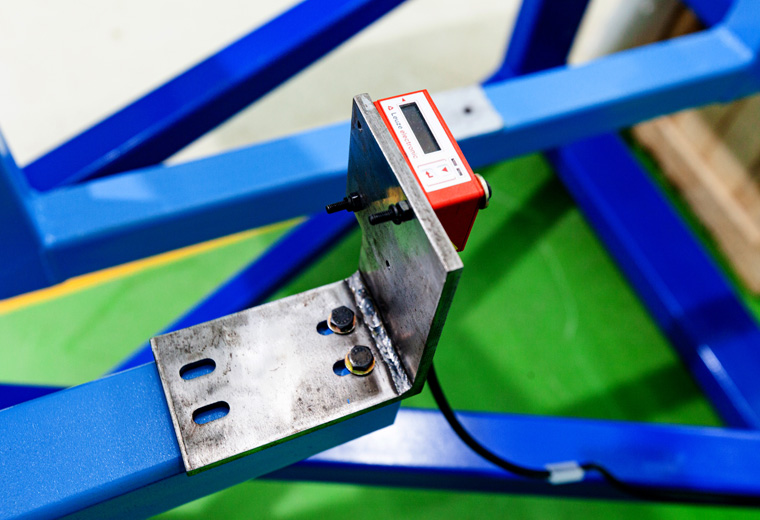

The final design was a compact machine with leveling and safety features and fixtures to accommodate various shape and size objects.

Key Engineering Solutions

Solutions

Timetooth initiated the project with study of the object followed by conceptualising the machine configurations. Further machine design calculations and error sensitivity analysis was done. Timetooth leveraged virtual simulations for Static and Dynamic behaviour predictions of machine and object assembly.

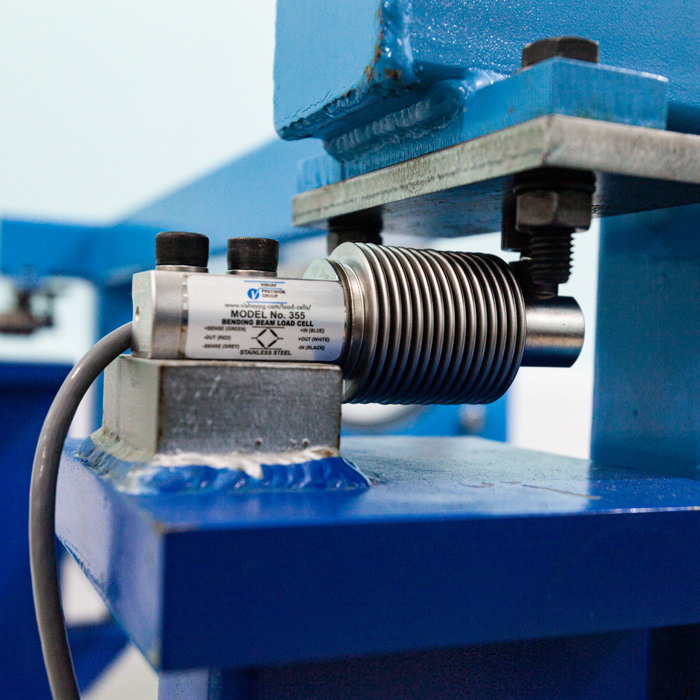

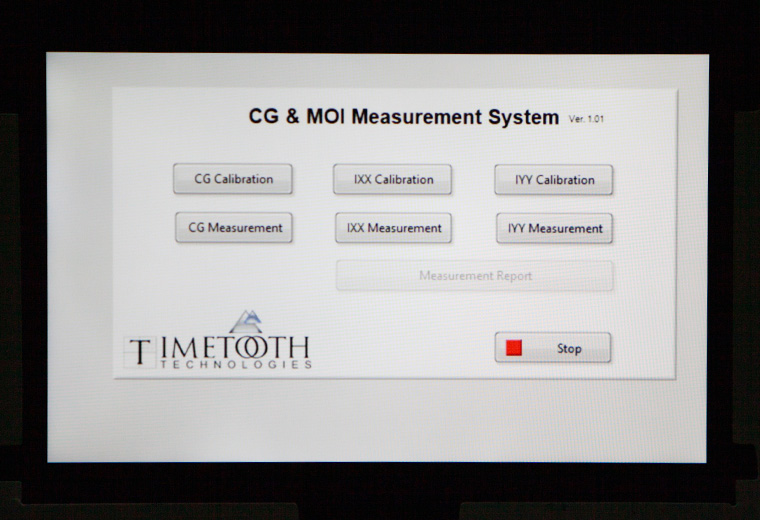

Concurrently, design and selection of high resolution and accuracy sensors and data acquisition systems was executed. Industrial grade display system was configured and Custom software was developed. The final design was a compact machine with leveling and safety features and fixtures to accommodate various shape and size objects. Manufacturing was carried out with controlled GD & T and conformance to rigorous quality management systems. The machines were inspected using Coordinate-measuring machines and extensive calibration and testing was carried out before final dispatch.

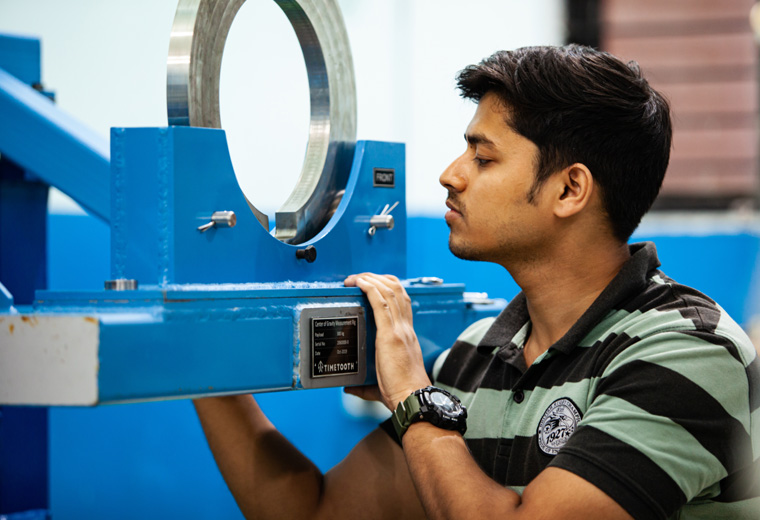

Timetooth team completed the installation and commissioning on site with live object measurement trials ensuring complete customer satisfaction.