Escorts was able to patent this invention. Till 2023, it remains the only PnC crane maker to offer a 29 ton (recently augmented to 30 ton) capacity model.

Key Engineering Solutions

Solutions

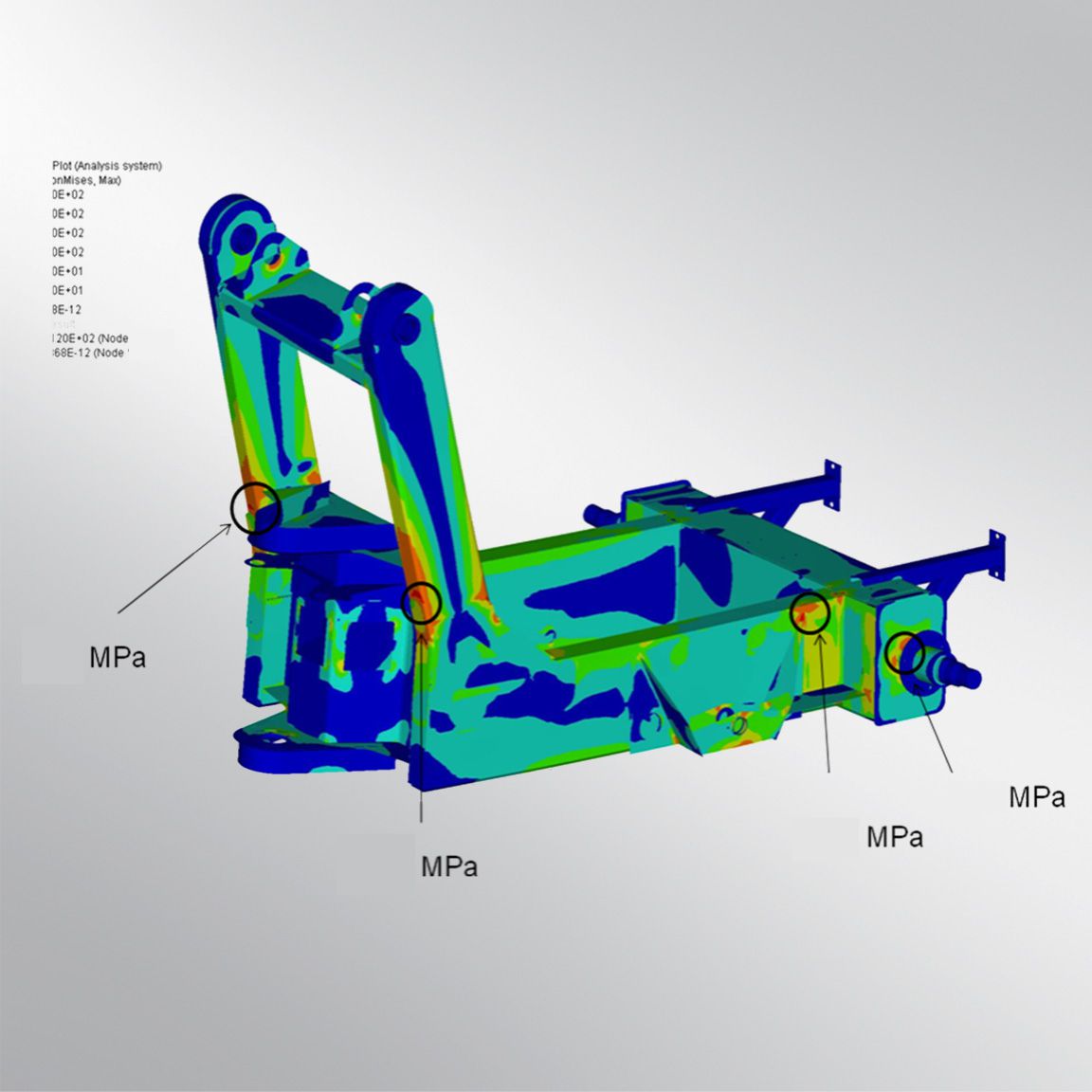

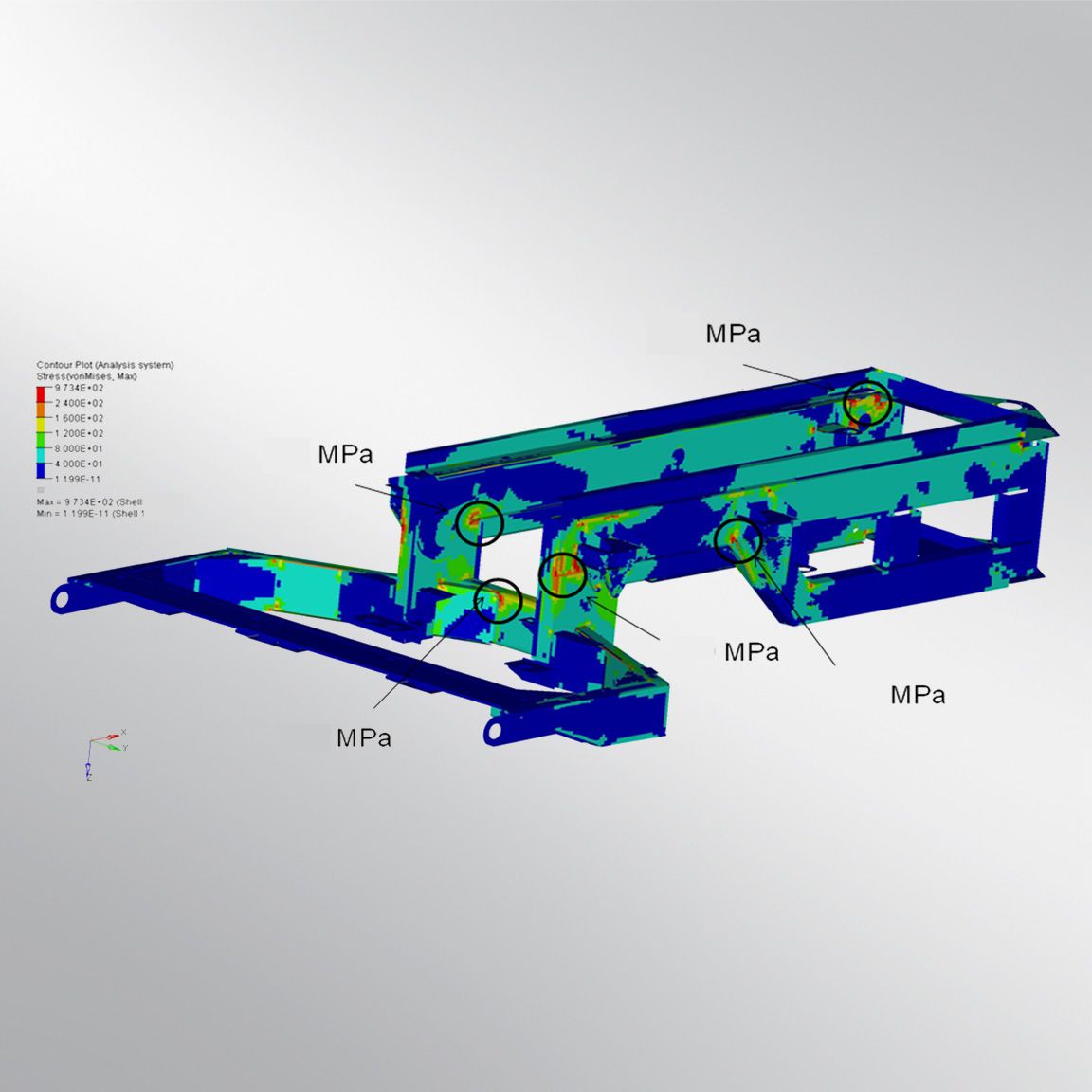

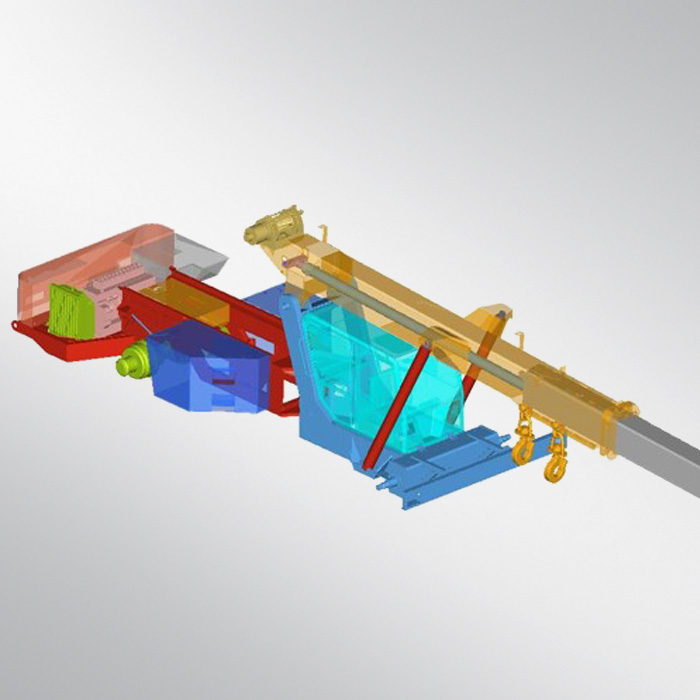

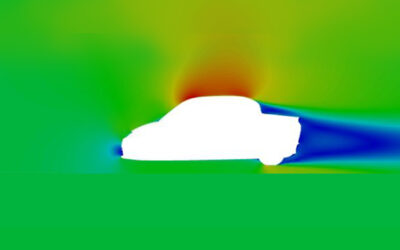

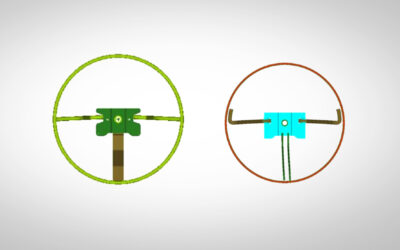

Timetooth applied Multibody Dynamic simulations to completely capture the crane movements – from boom extension, to lift, to steering. This “xray” into the crane’s dynamical behavior led to the discovery of a unique design for the crane’s articulated joint. “Similar to how humans carry a heavy suitcase on one side, by slightly leaning to the other side” the inventor, Rajesh Rao, explained.

Escorts was able to patent this invention. Till 2023, it remains the only PnC crane maker to offer a 29 ton (recently augmented to 30 ton) capacity.

Key Highlights