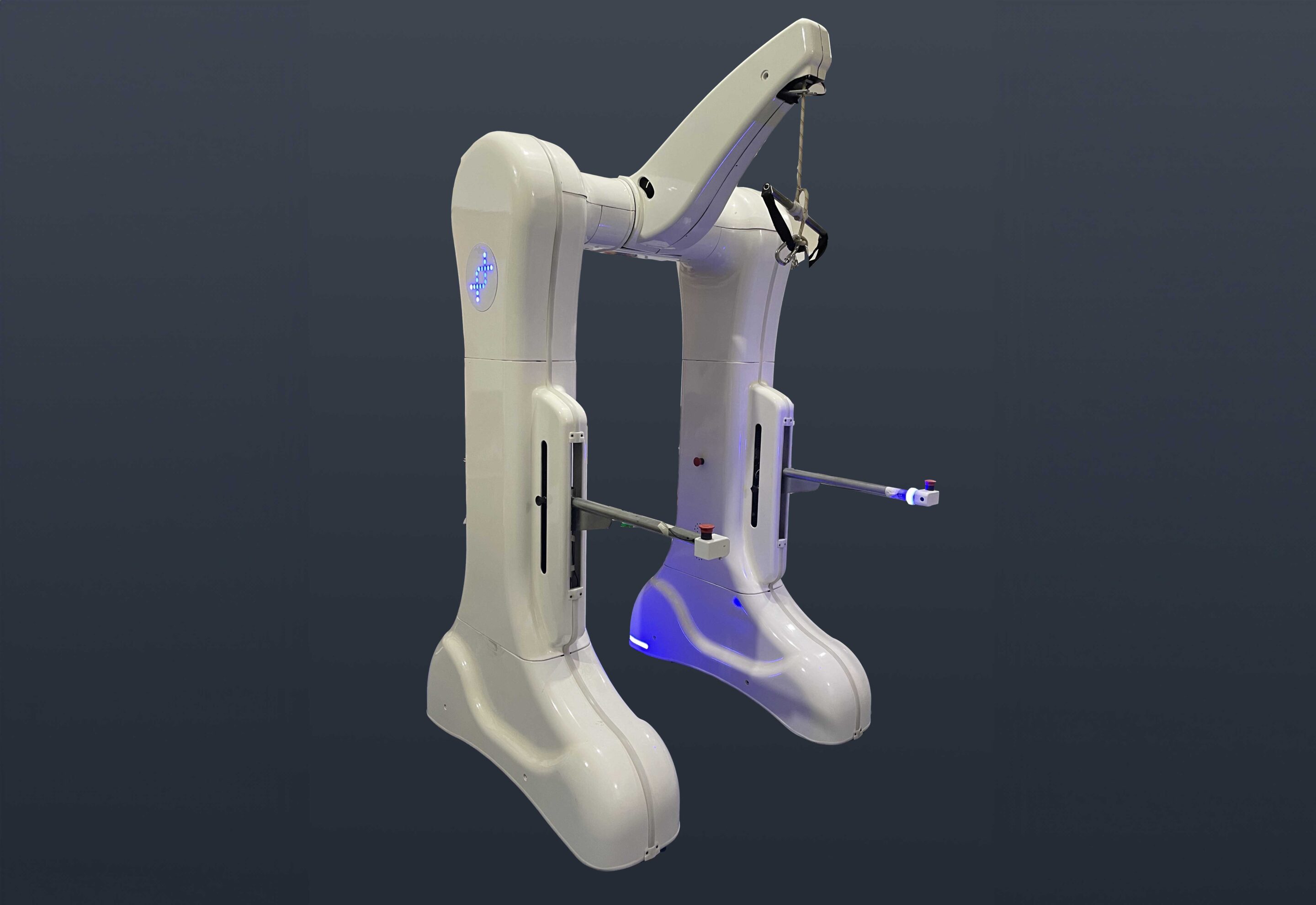

FRP manufacturing processes were employed for enhanced durability, aesthetic finish and ease of manufacturing.

Key Engineering Solutions

Solutions

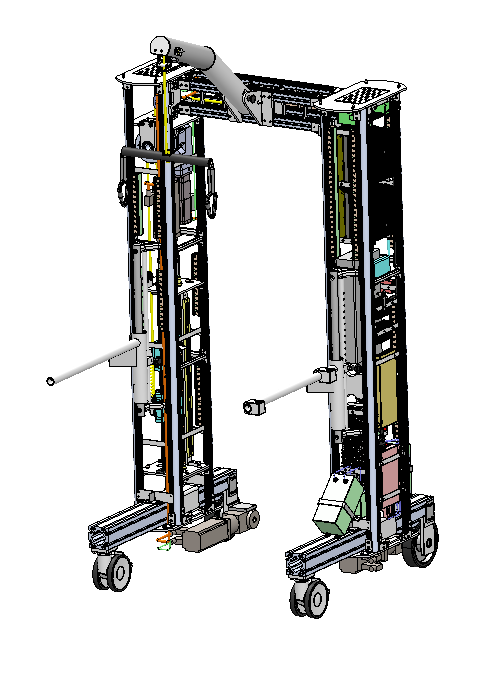

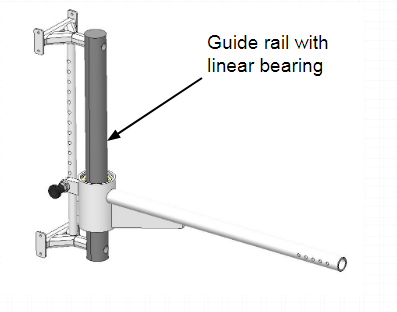

Timetooth initiated the design by studying the market and identifying critical components for Mobility Assisted Rehabilitation. Concept was developed with focus on structural optimisation and weight reduction. CAD modeling was carried out and alternate standard components were identified. FRP manufacturing processes were considered as it offers durability, light weightness, aesthetic finish and ease of manufacturing. A modular design approach was incorporated for better transportability and handling. Design was modified to accommodate wheelchairs and length of boom was increased to provide handrail grip to patients while the system runs in reverse direction. Further Design modifications were made as per mechanical interfacing including use of insert plate, snap rivets, positive locking (Hidden), etc.

Manufacturing was done under close supervision by aligning different vendors to execute various steps.