Timetooth's team visited the client's manufacturing facility and designed components to align with the client's manufacturing capabilities.

Key Engineering Solutions

Solutions

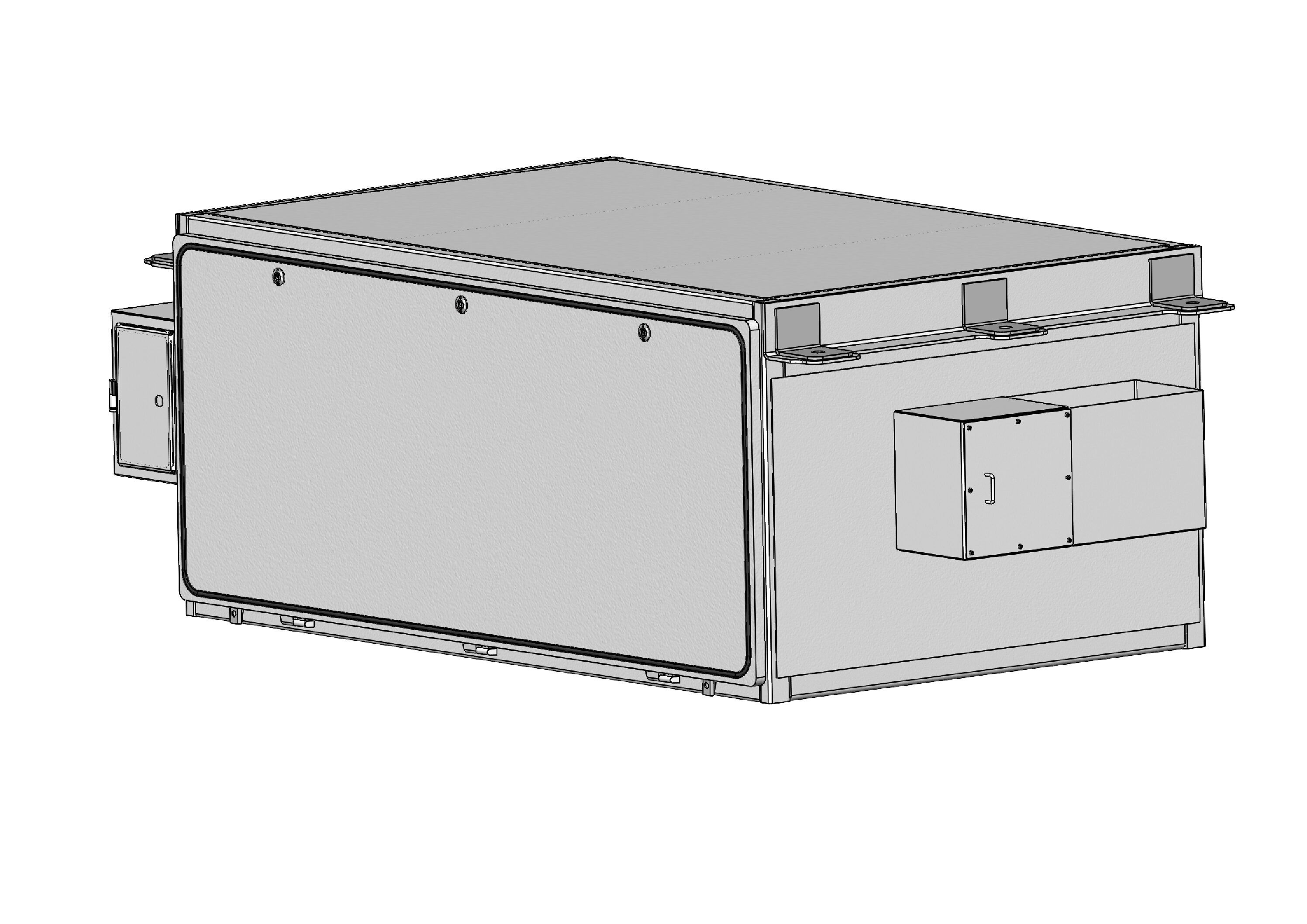

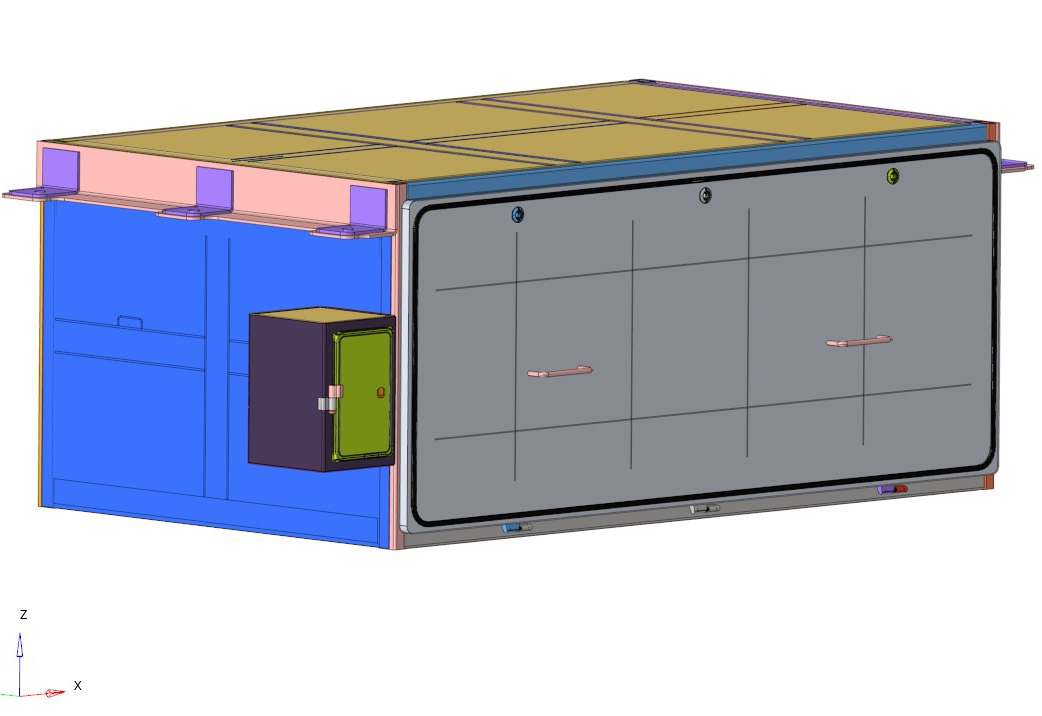

Timetooth began the project by studying the railway standards applicable to the design. A battery enclosure was modeled based on the external dimensions and mounting points provided by the client.

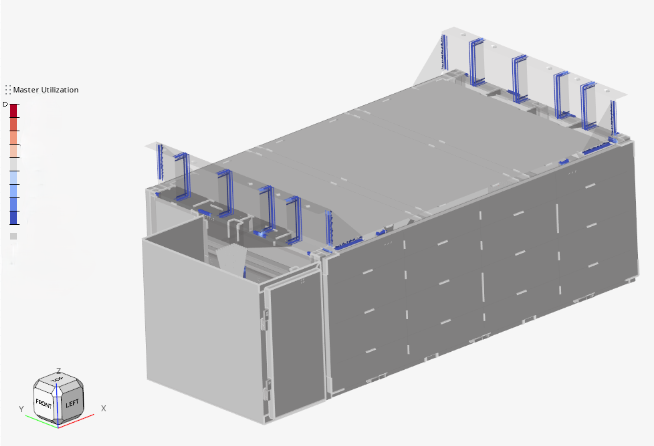

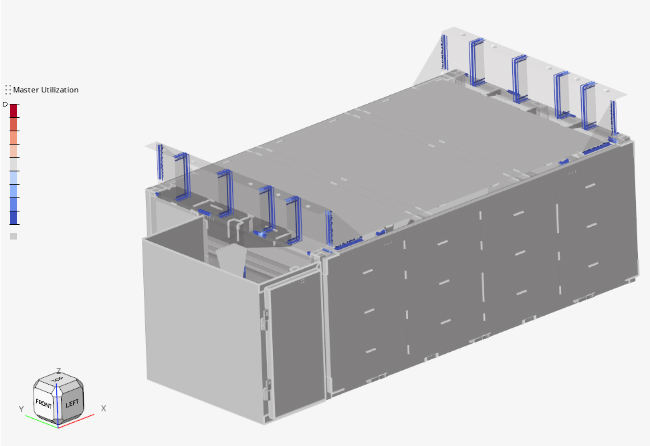

A modal analysis was conducted to evaluate the mode shapes and natural frequencies. Further structural analysis, including equivalent static and buckling analysis, was performed as per EN 12663. Additionally, weld fatigue assessment was carried out following DVS 1612 guidelines.

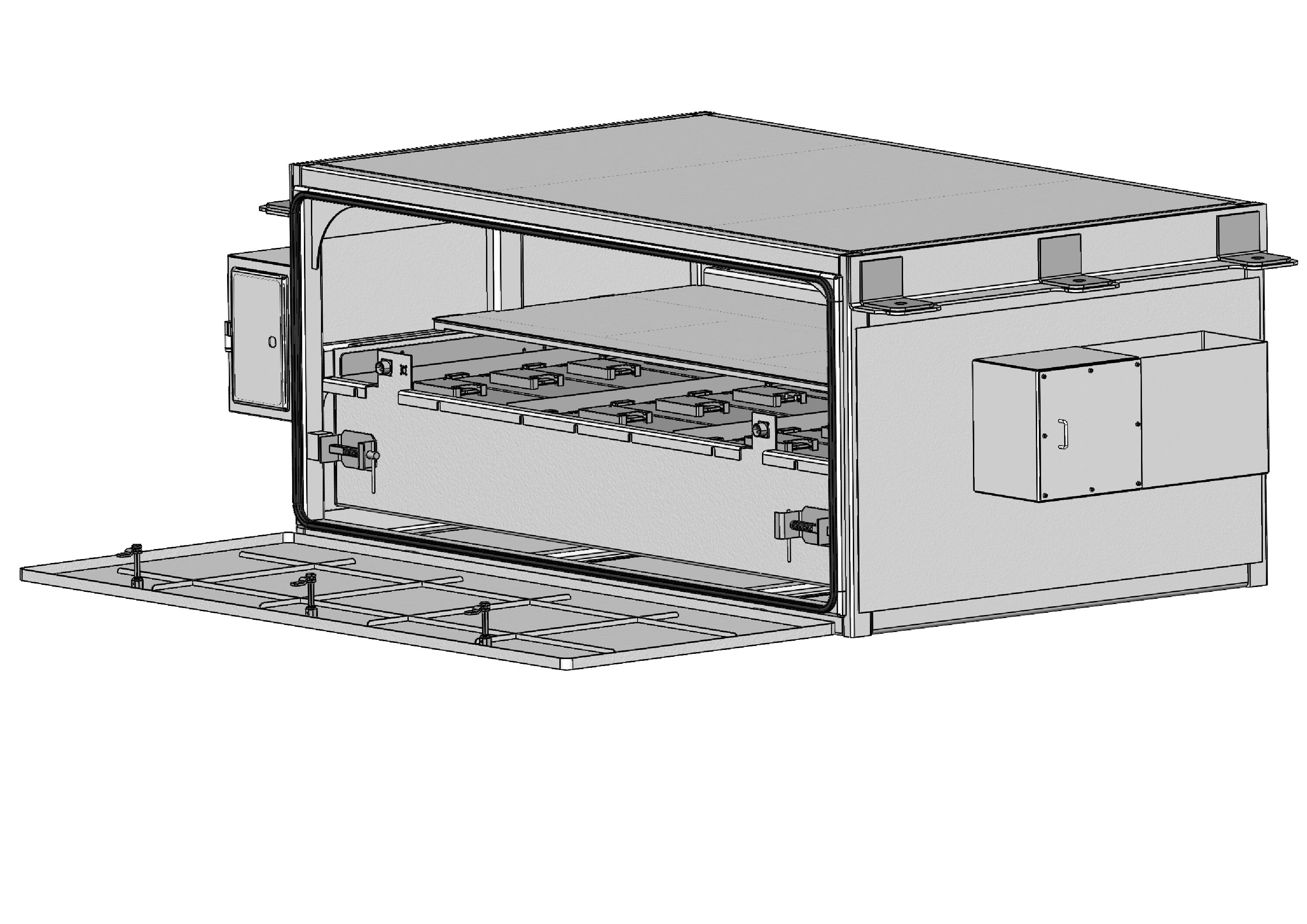

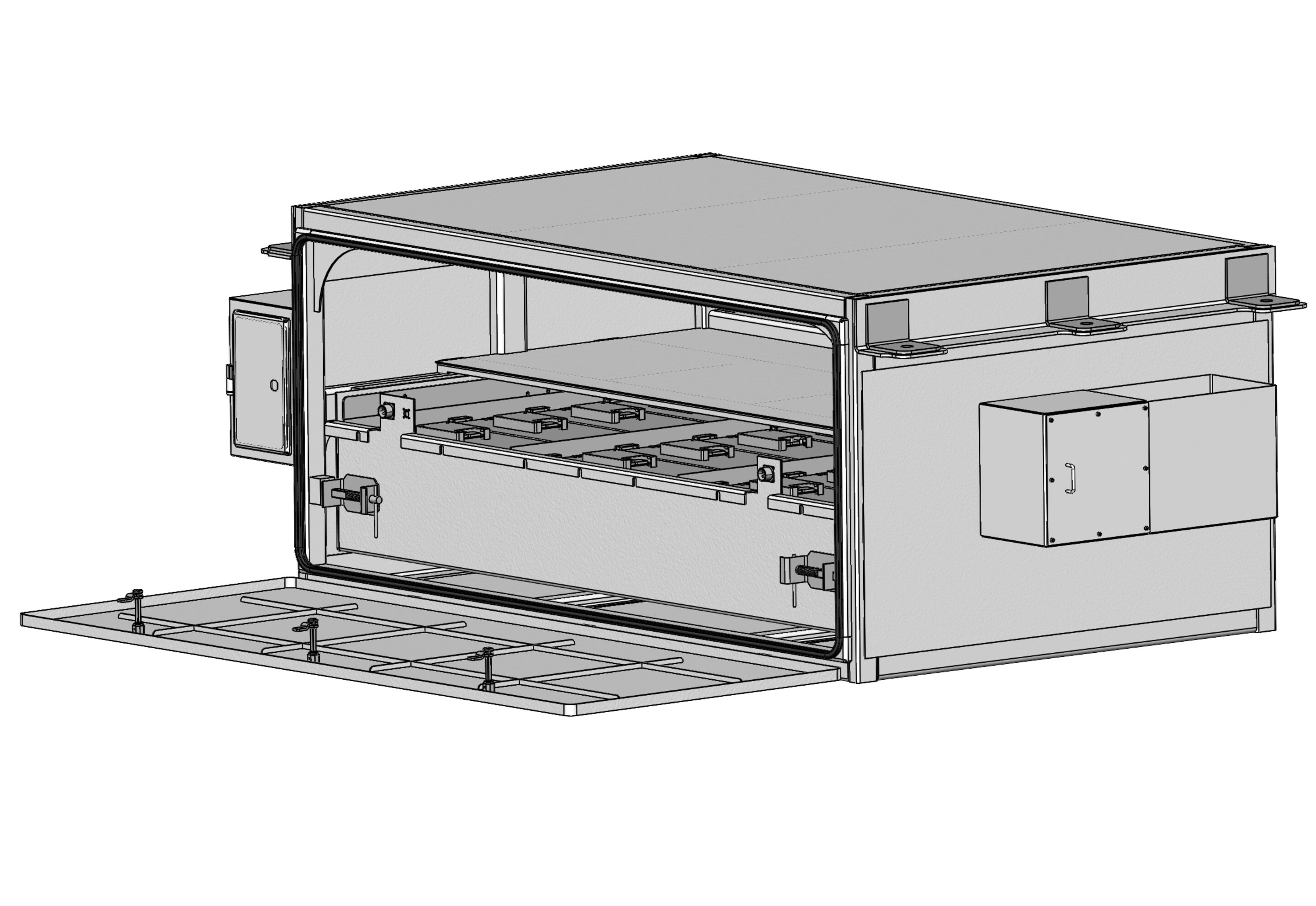

Simulation results were analyzed to identify weak points, and design iterations were made to improve strength and rigidity. The design incorporated Fire Safety norms as per EN 45545. The design also included an IP 65 rating for the electric box, sockets, and cable glands mounted in outdoor areas, and an IP 54 rating for the battery box. Timetooth’s team visited the client’s manufacturing facility and designed components to align with the client’s manufacturing capabilities.

Once the design was finalized, relevant mechanical accessories such as latches, gaskets, and hinges were selected and shared with the client. The final model also included provisions for mounting electrical accessories, routing, and mounting lugs. All manufacturing and welding drawings were shared with the client.