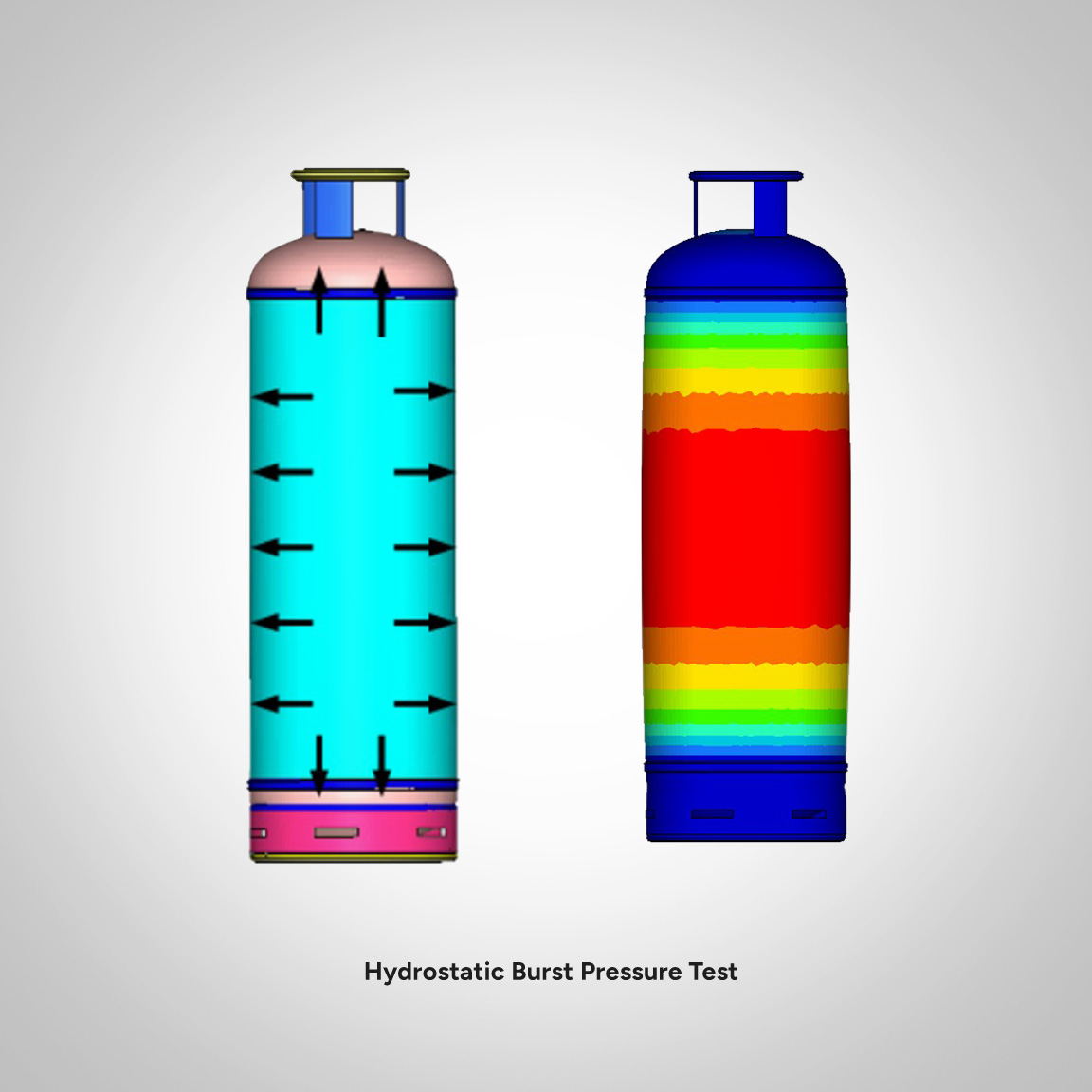

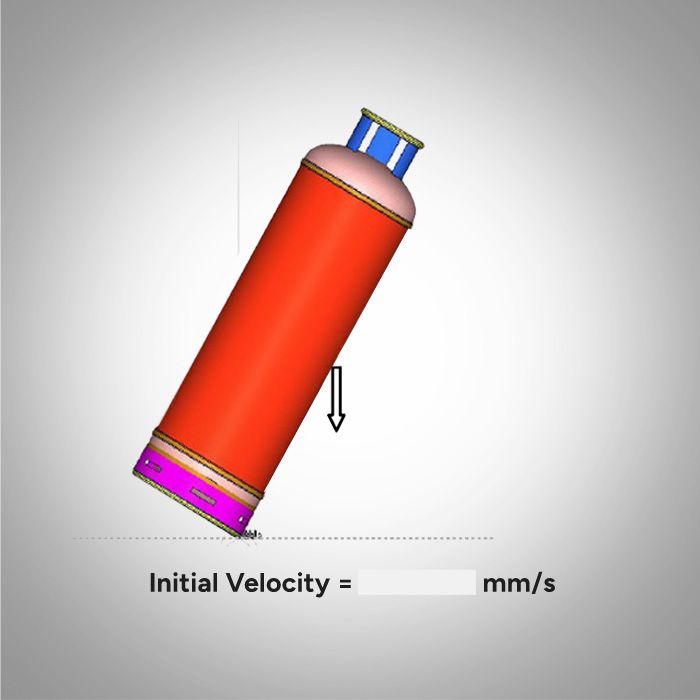

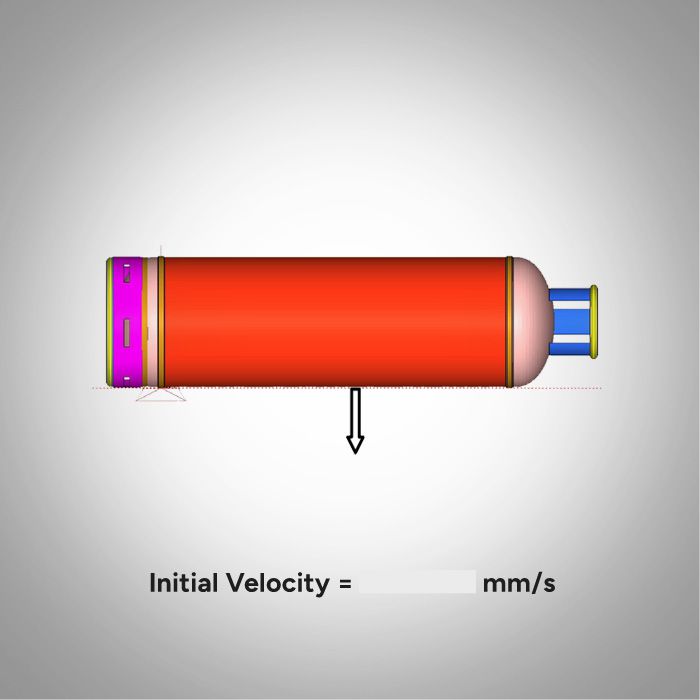

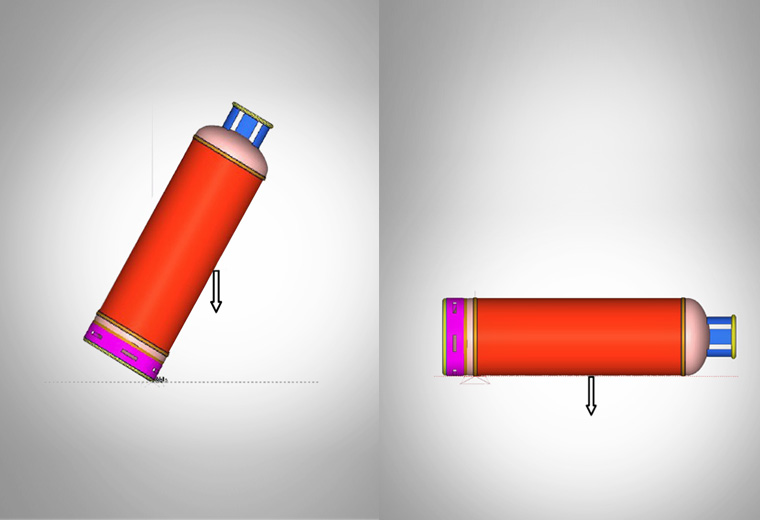

Timetooth leveraged non-linear quasi static and non-linear dynamic analysis to predict structural stresses and deformations.

Engineering Design Analysis

Solutions

Timetooth started the project by modifying the base design of steel cylinders for consideration of aluminum fabrication. The ISO standards were studied and various tests were mapped to simulation boundary conditions. Timetooth leveraged non-linear quasi static and non-linear dynamic analysis to predict structural stresses and deformations. Tests included yield pressure, burst pressure, drop test, volumetric expansion and mechanical properties in different loading conditions. The results were interpreted and design modifications were shared for a high performance product.

The client implemented the design suggestions, fabricated the prototype and executed the tests. The prototype cleared the acceptance criteria of the tests.