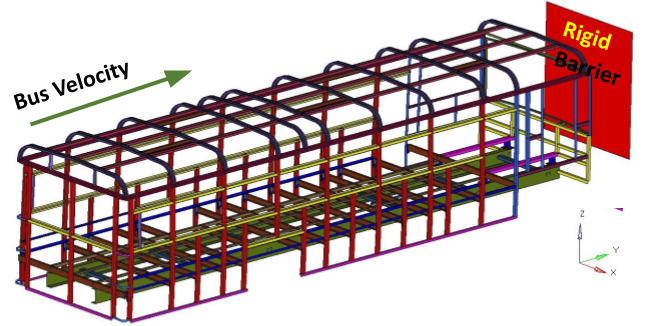

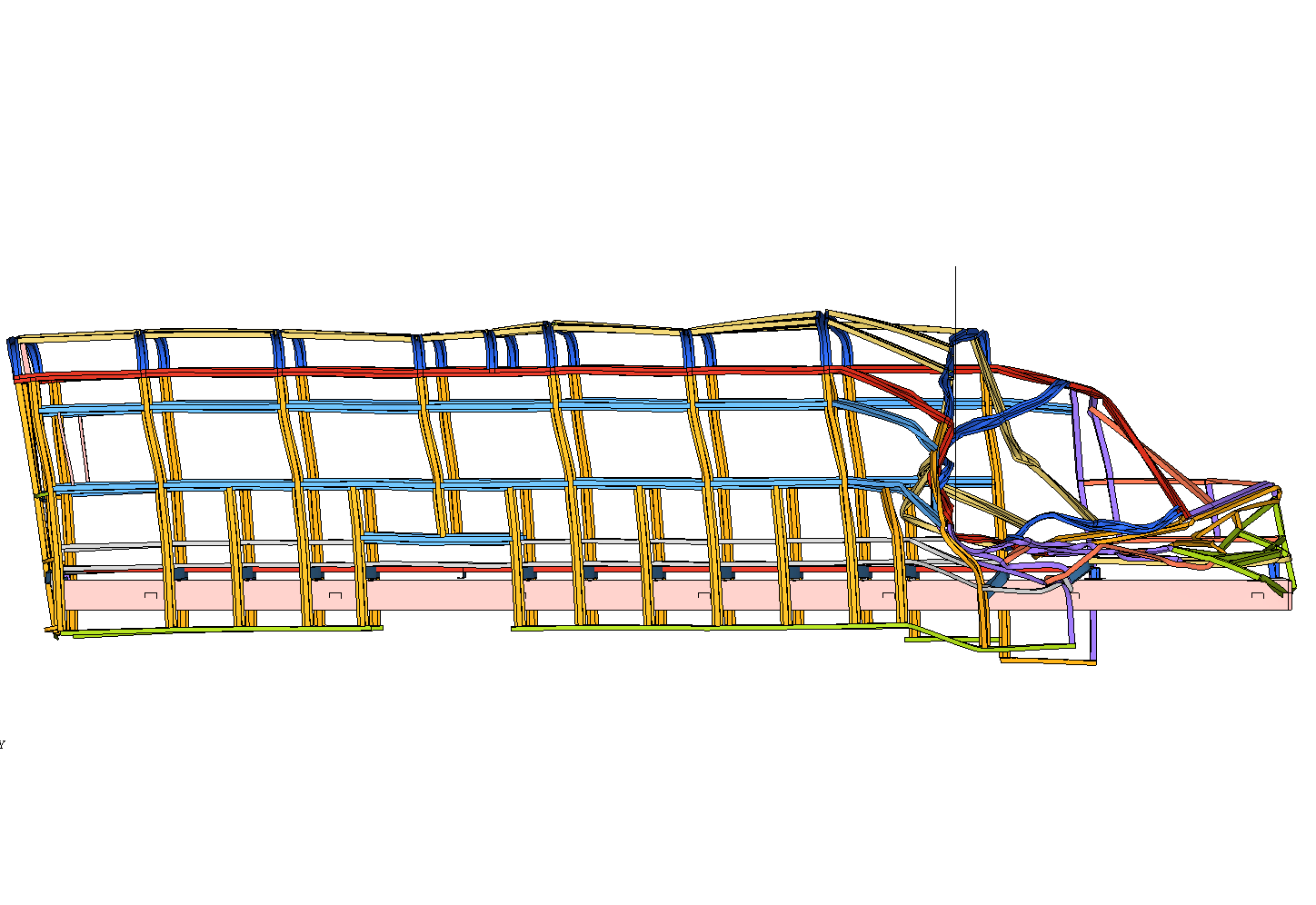

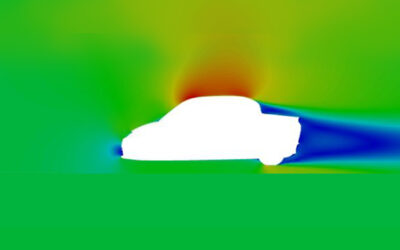

Nonlinear dynamic crash analysis was carried out on complete structures for full frontal and half frontal crash scenarios deriving precise load cases.

Key Engineering Solutions

Solutions

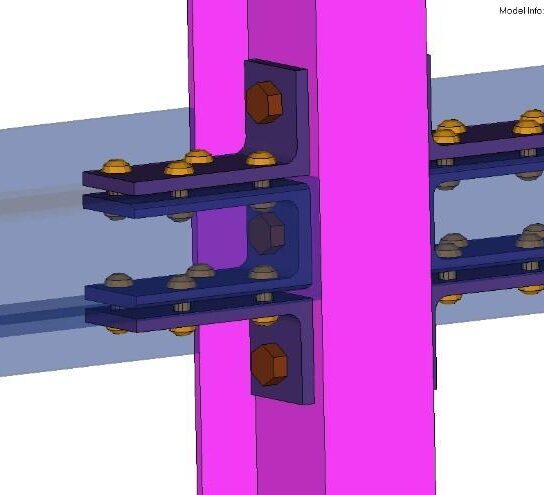

Timetooth initiated the project with the Data Collection and Preliminary 3D CAD Modeling of the vehicle. Measurements of mule vehicle and workshop visits were carried out to capture the construction details. Preliminary research led to the identification that a majority of the bus accidents occur due to frontal impact and joints form the weakest link in the bus body structure.

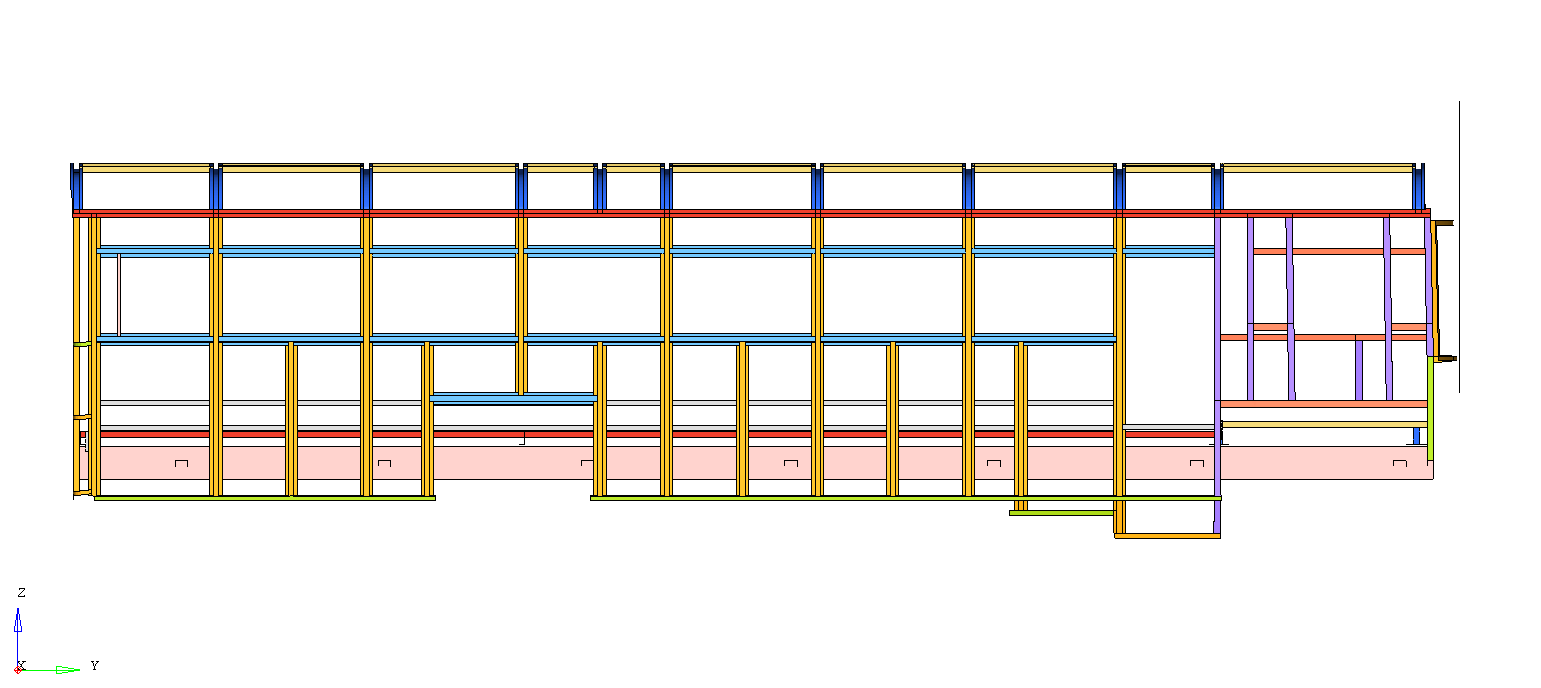

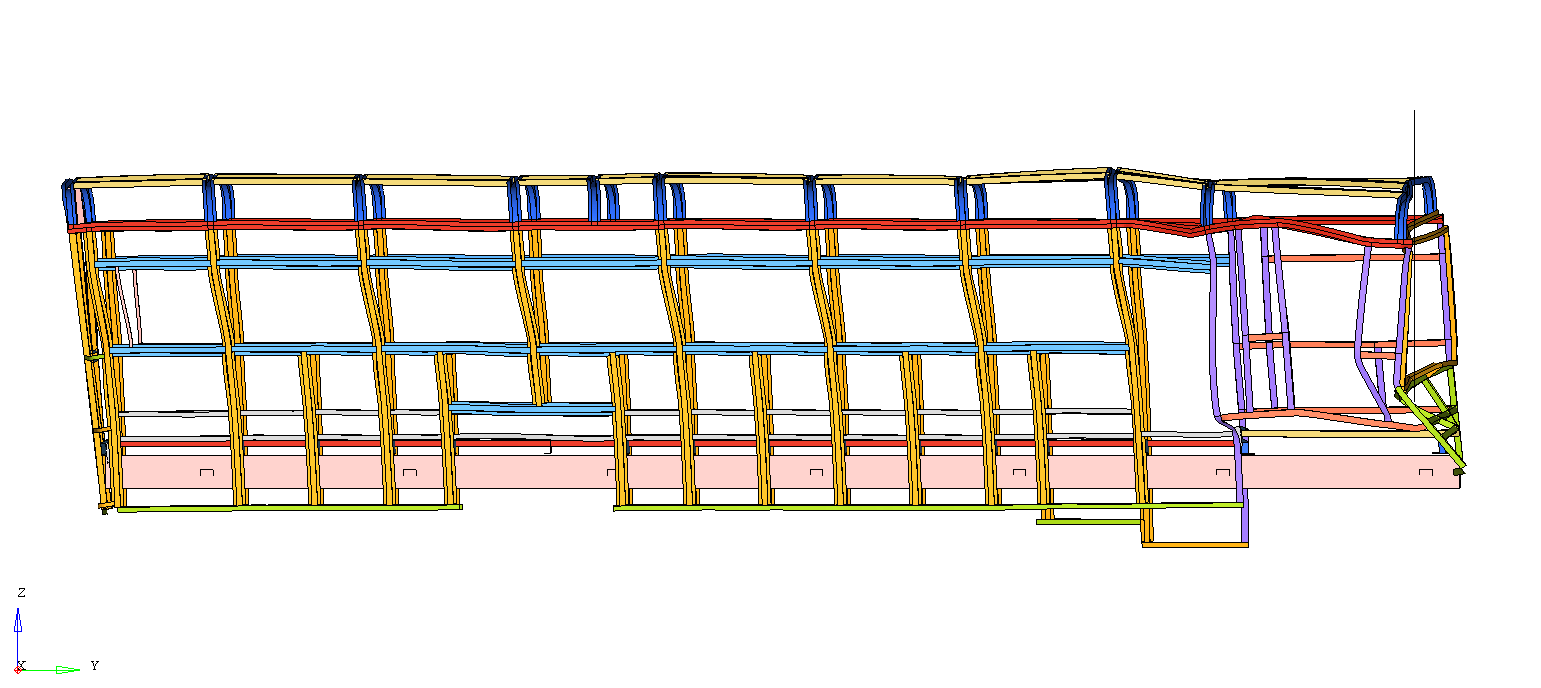

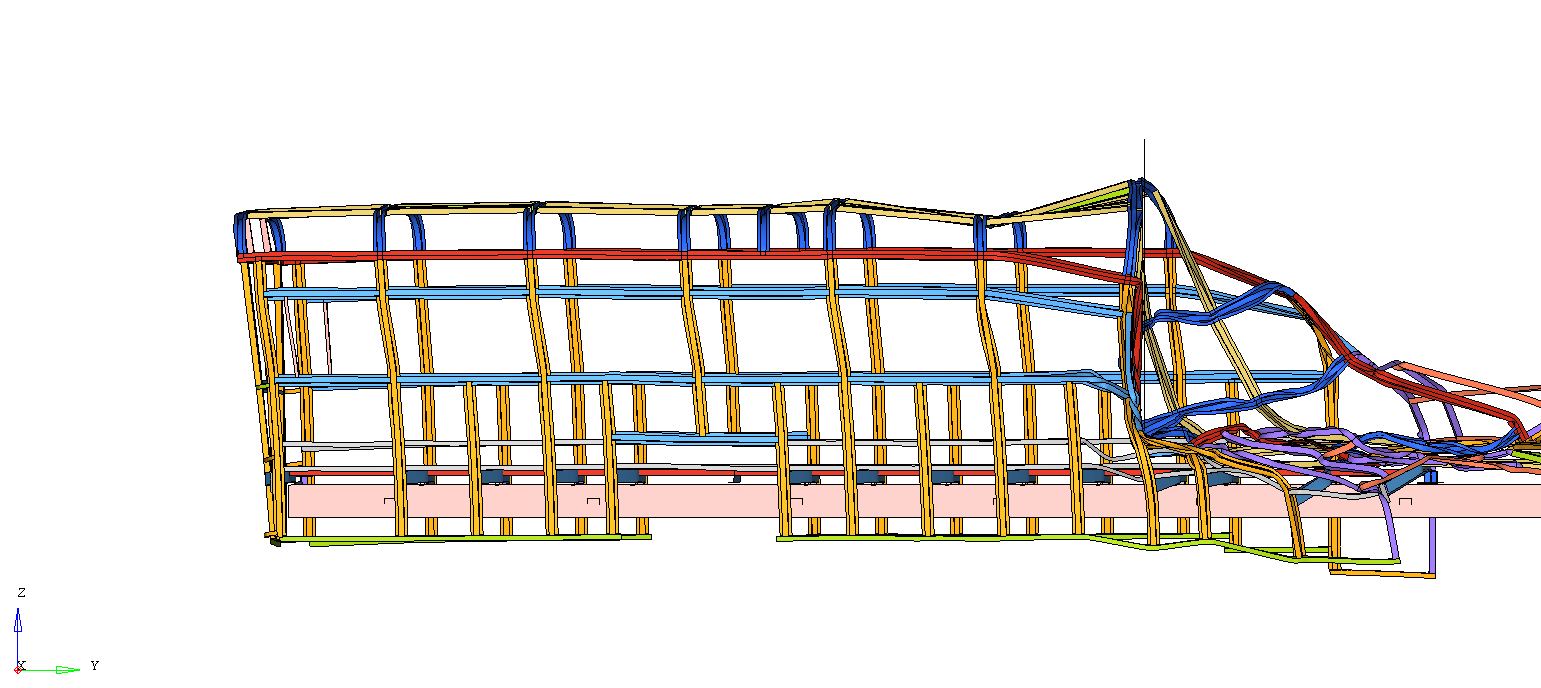

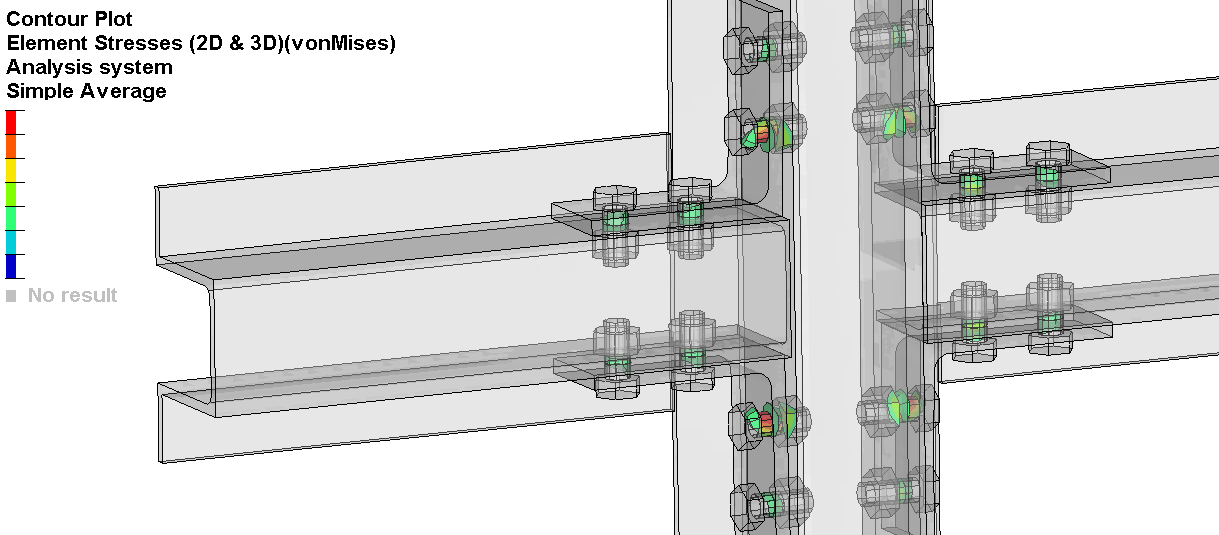

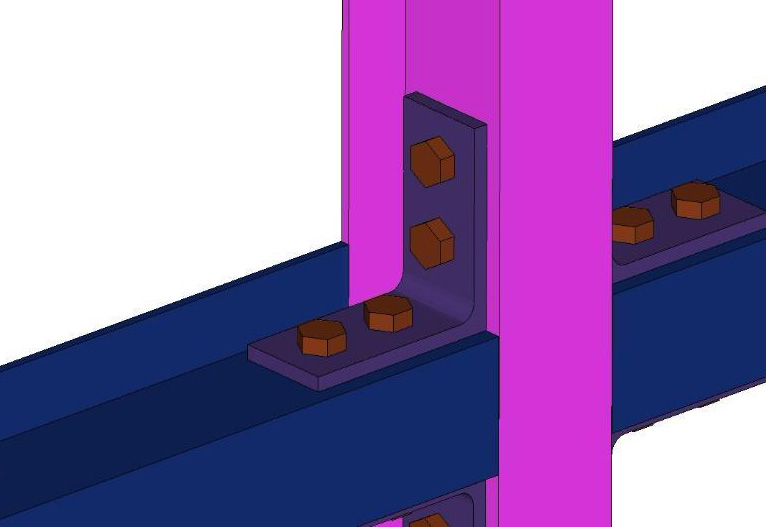

A FE mesh model from 3D CAD data was developed by applying loads and boundary conditions in accordance with physical behavior during impact incorporating appropriate connectivity and material properties. Further nonlinear dynamic crash analysis was carried out on complete structures for full frontal and half frontal crash scenarios deriving precise load cases and boundary conditions crucial for micro-level joints optimization.

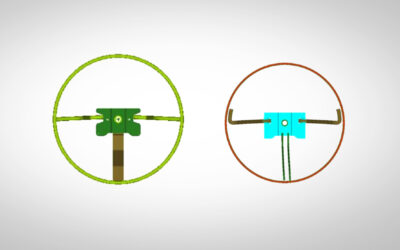

Critical joints were independently analyzed to identify weak spots and gain insights into structural behavior under various loading conditions. Cumulative assessment of simulation results and judicious design modifications with consideration for manufacturability and assembly feasibility was done. Design directions to enhance Joint and structure strength were shared with the client. Working closely with the client’s design team the design was finalized incorporating the suggestions.