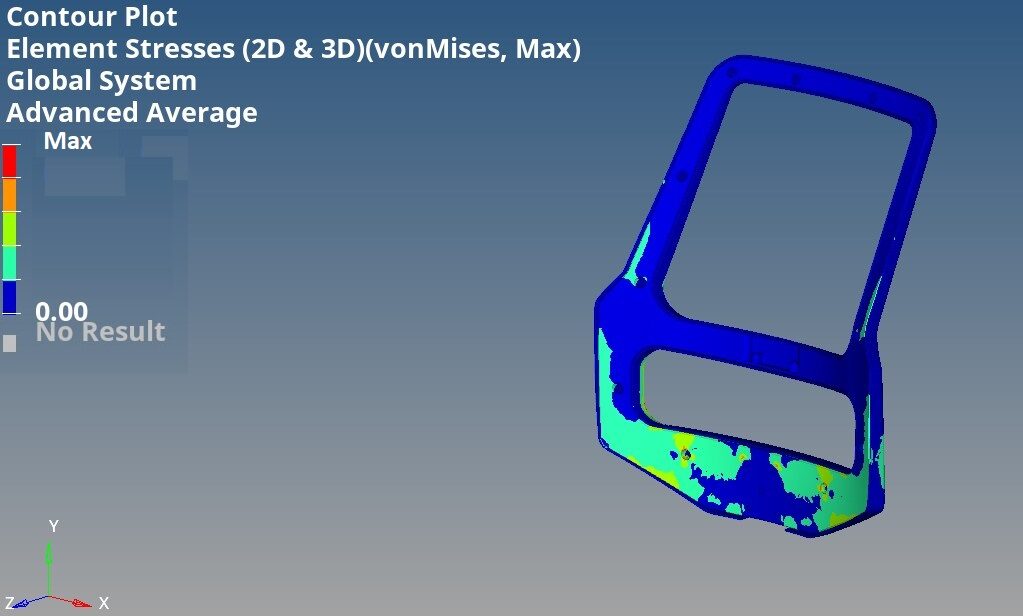

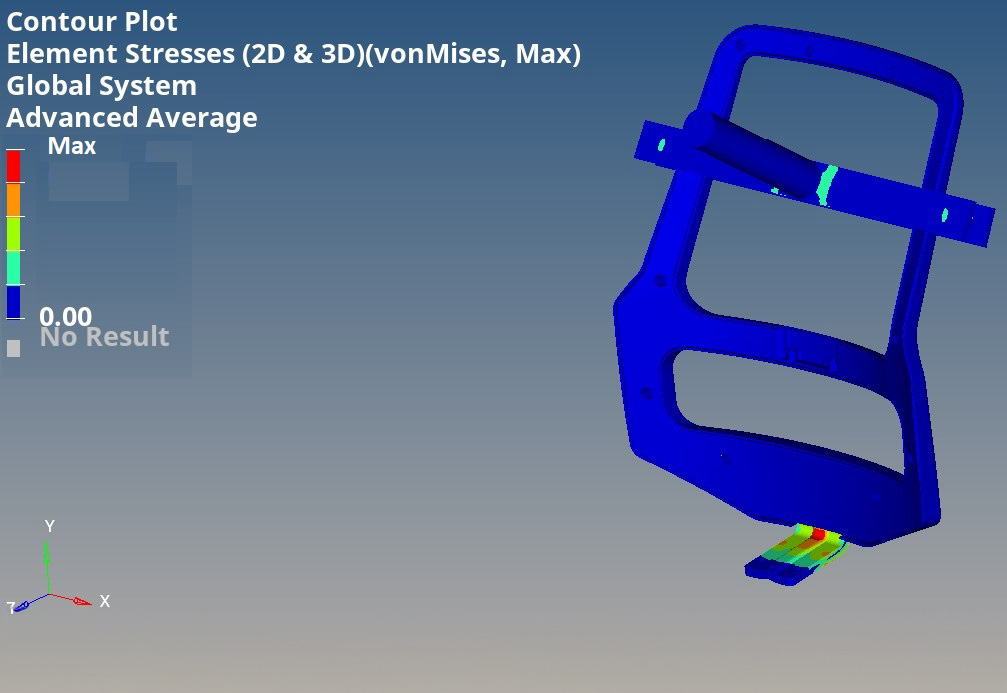

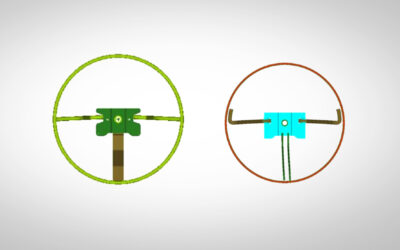

Interpretation of simulation results found that J-bar and localized areas of the backrest where J-bar is mounted showed high stresses.

Key Engineering Solutions

Solutions

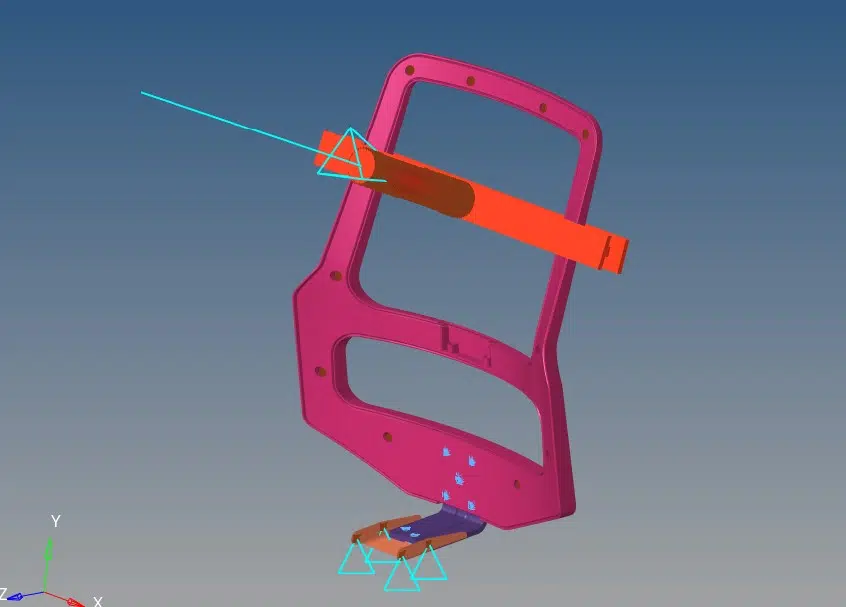

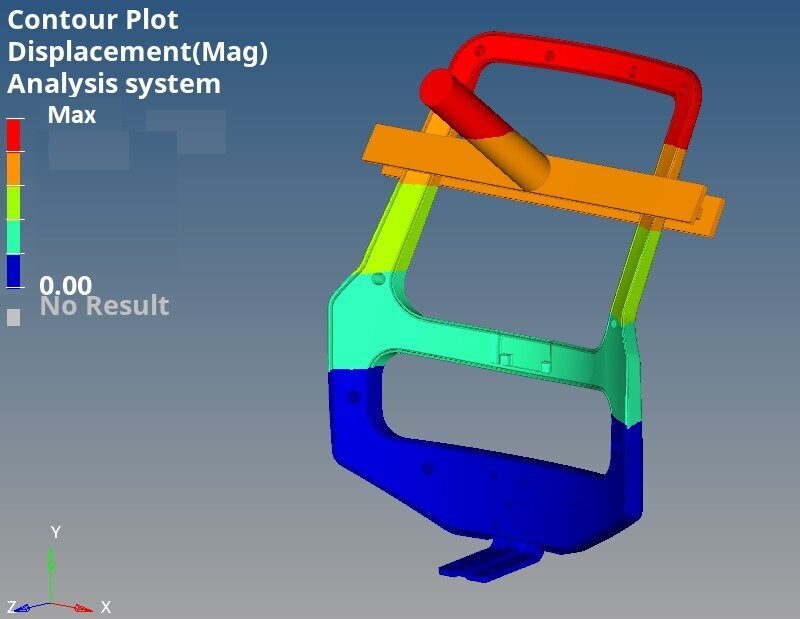

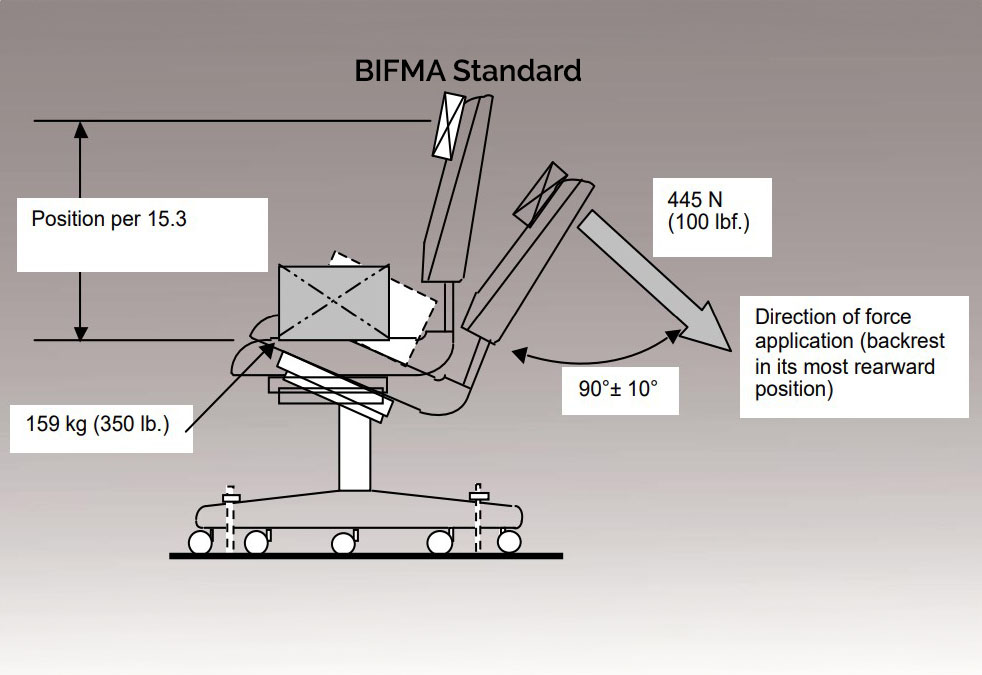

Timetooth performed structural analysis to predict stress and displacement in the backrest assembly to evaluate and optimize it. The backrest assembly was then meshed as per benchmarked quality, and analyzed with the necessary boundary conditions and loads.

Further simulation results were interpreted and it was found that J-bar and localized areas of the backrest where J-bar is mounted showed high stresses. As per the assessment of simulation results specific design modifications to meet the required parameters were shared with the client.