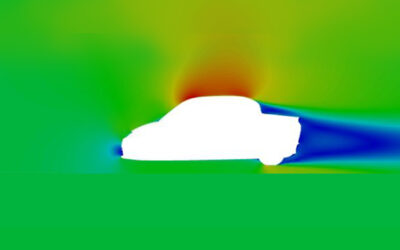

3D CFD simulations were employed to examine relative performance of each design by analyzing a single blade under a constant orthogonal flow of air.

Key Engineering Solutions

Solutions

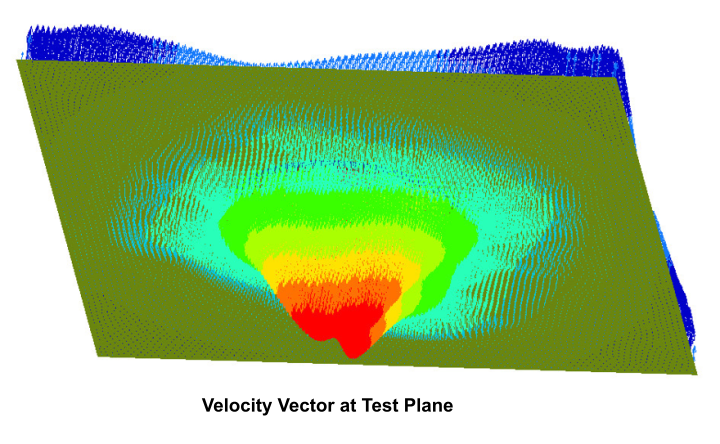

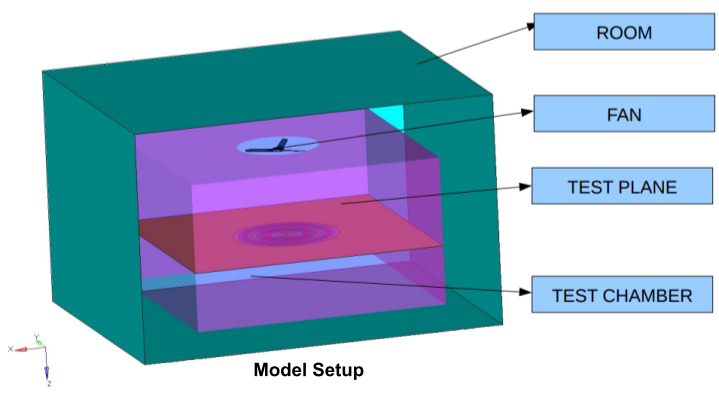

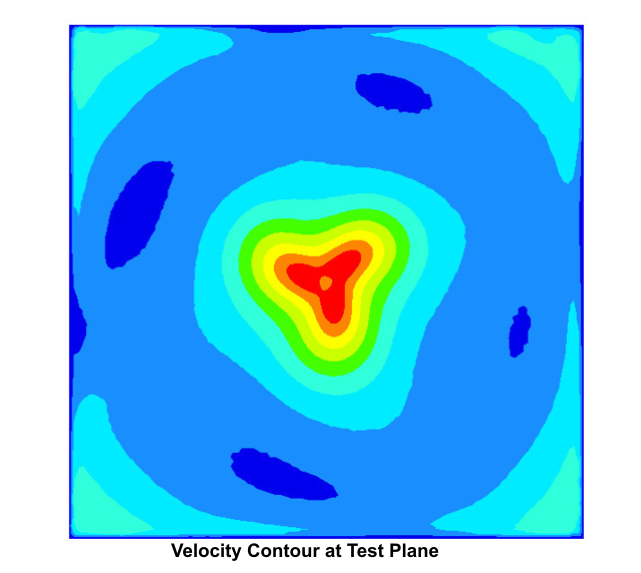

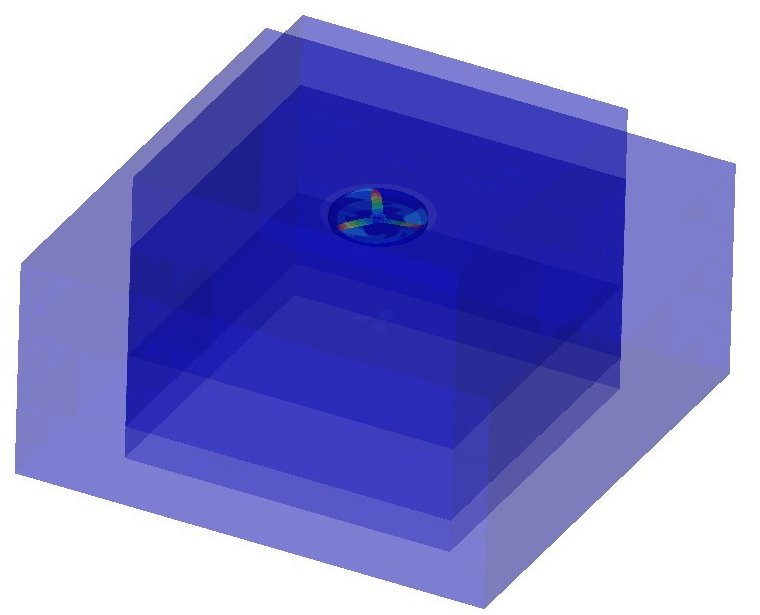

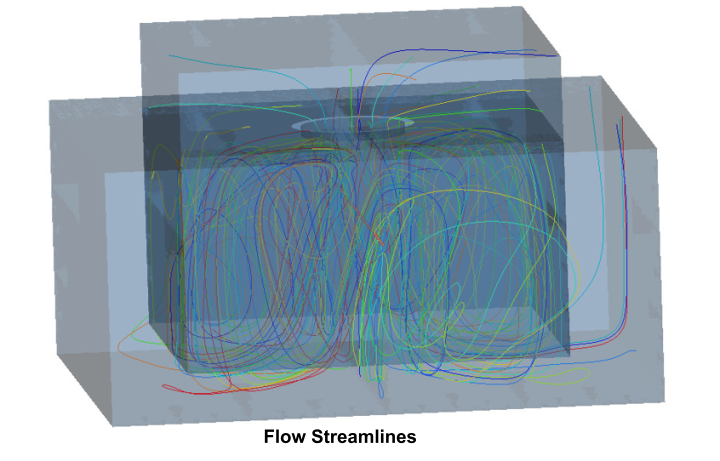

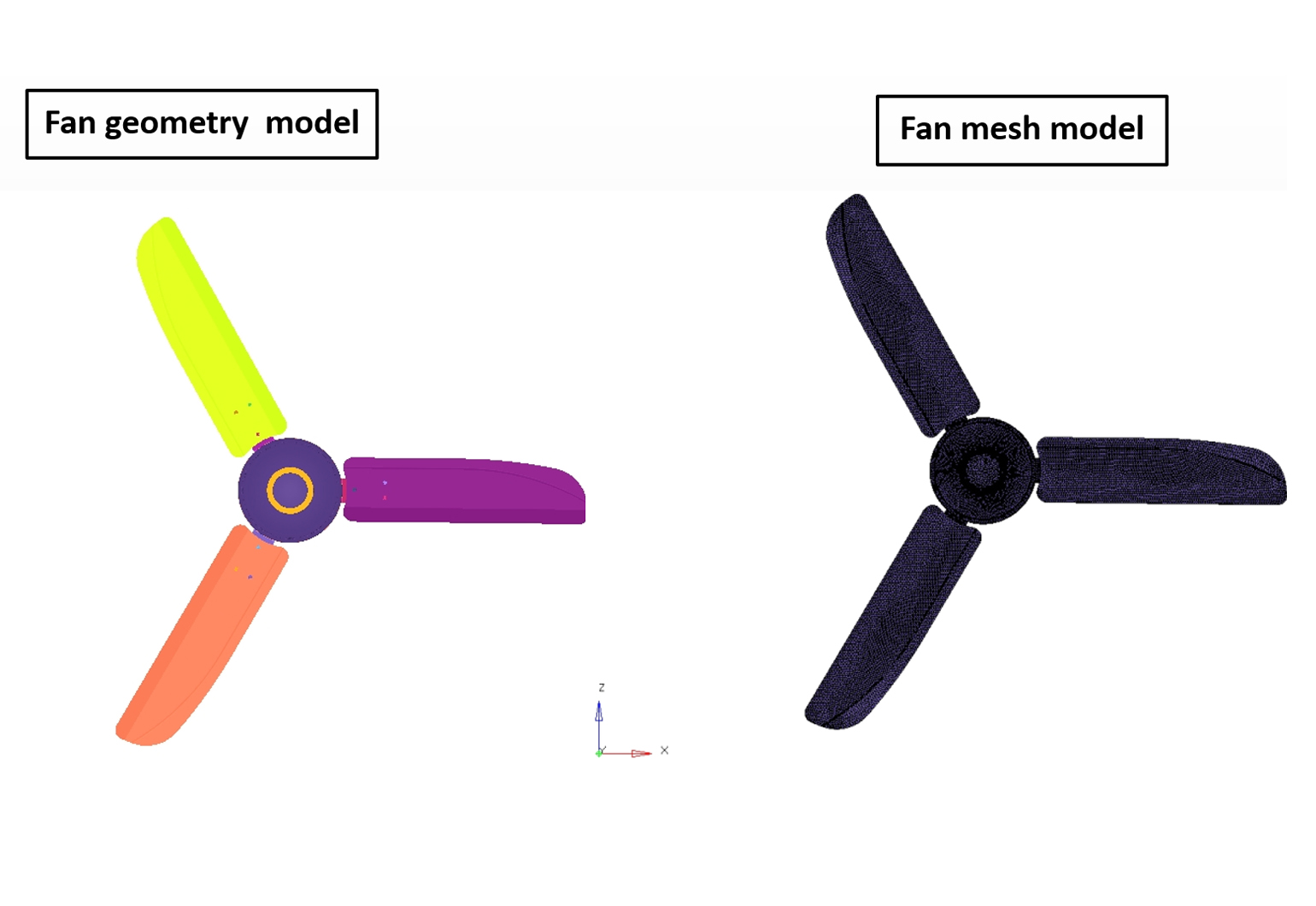

Timetooth initiated the project by modeling the existing fan. Simulations were carried out as per the IS 374 (1979) to calculate air delivery. The results obtained were correlated with physical test data to ensure accuracy and reliability.

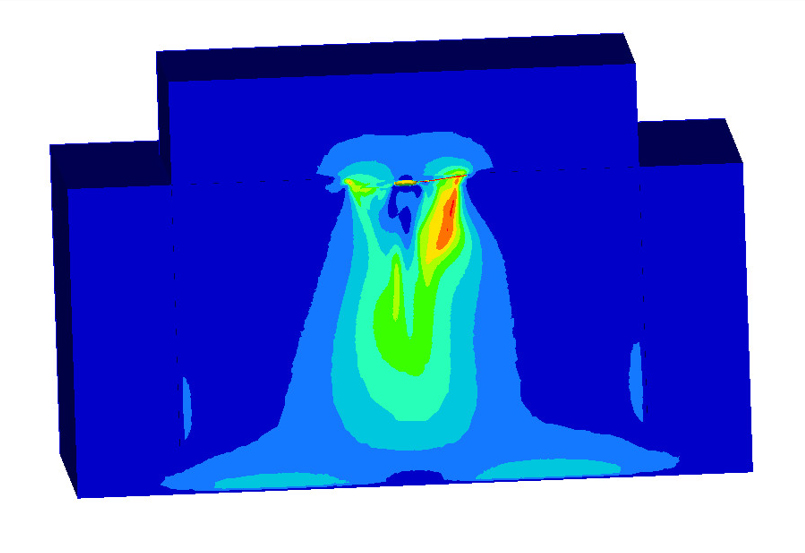

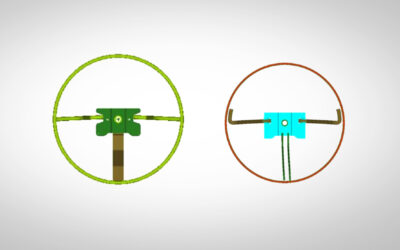

Different fan blade designs were analyzed for sensitivity. 3D CFD simulations were employed to examine relative performance of each design by analyzing a single blade under a constant orthogonal flow of air. The performance evaluation was based on the Lift-to-Drag ratio derived from the single blade simulations. The evaluation served as a key indicator for comparing the effectiveness of the various fan blade configurations. Study of motor output power predictions & fan drag torque were done.

Further to arrive at optimized design modifications the fan blade design was refined to enhance overall performance, incorporating the findings from the sensitivity study and simulations. The final design along with results were shared with the client.