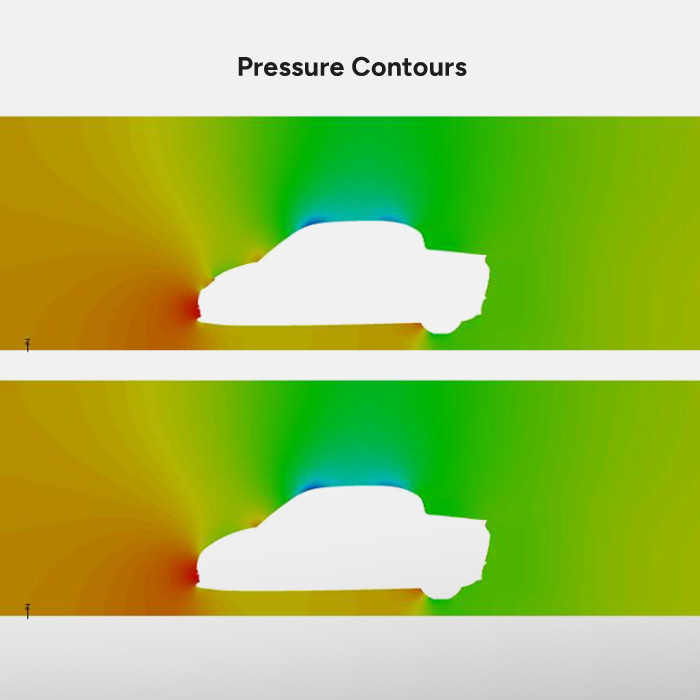

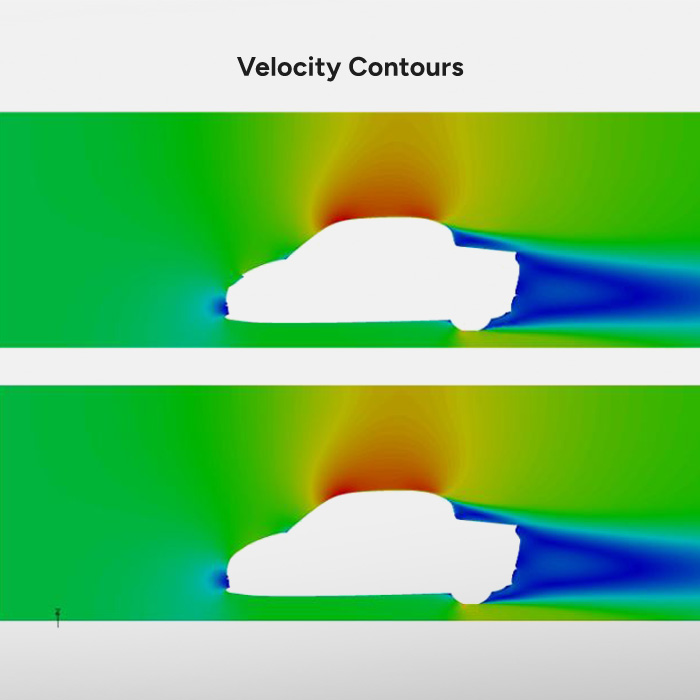

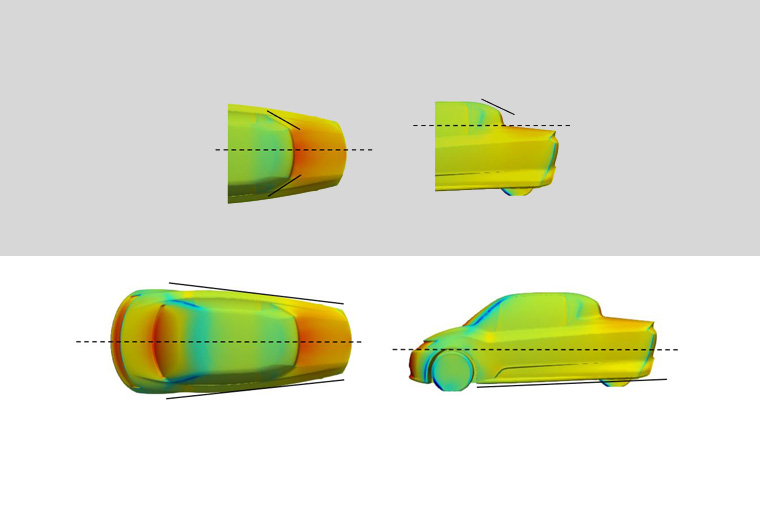

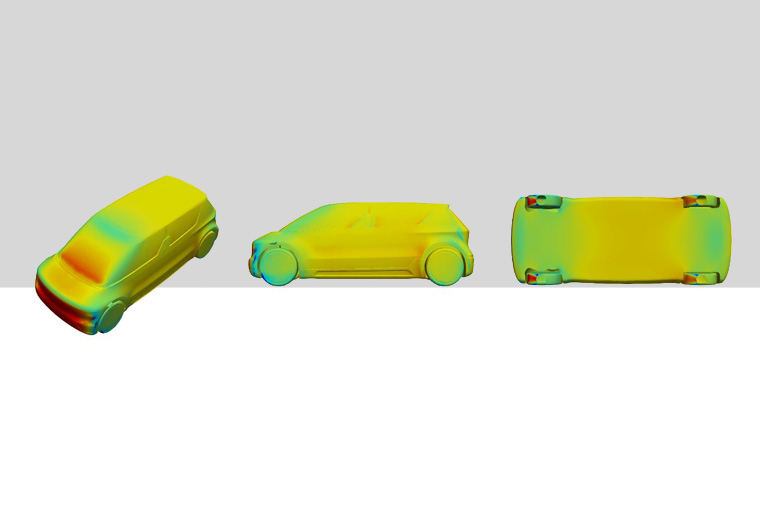

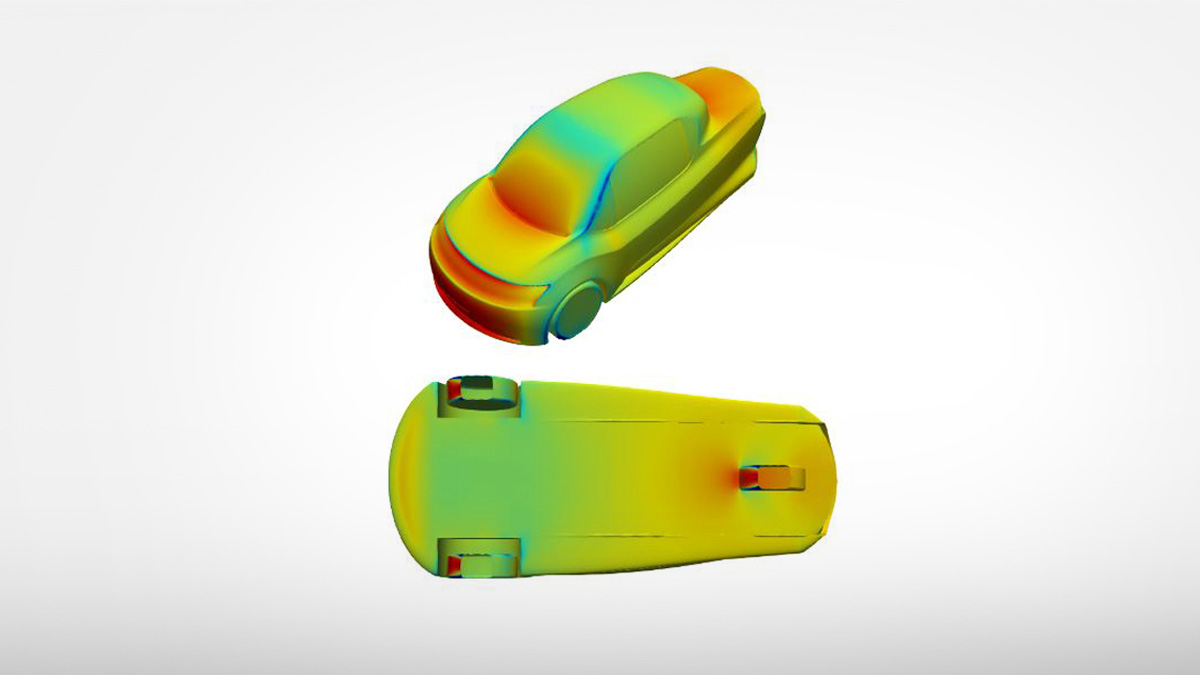

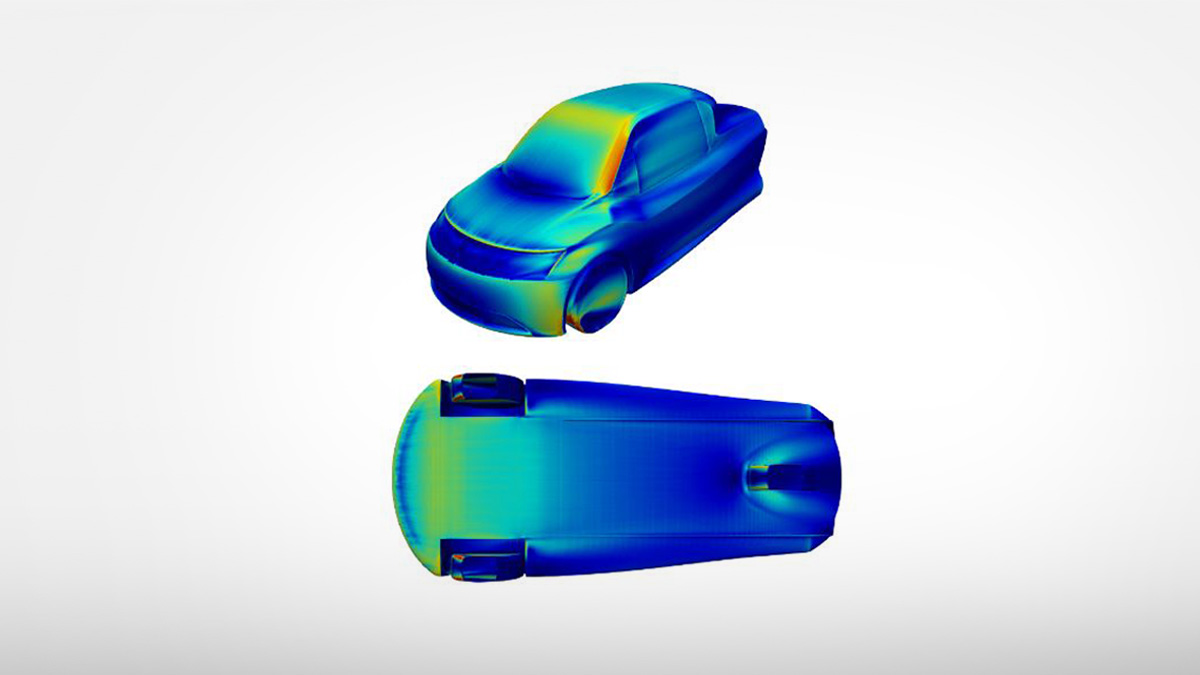

For calculating the fuel efficiency of the initial design of the car, Timetooth leveraged advanced CFD analysis to predict pressure contours, velocity contours and wake formations.

Engineering Design Analysis

Solutions

For calculating the fuel efficiency of the initial design of the car, Timetooth leveraged advanced CFD analysis to predict pressure contours, velocity contours and wake formations.

OpenFoam solver was customized with established international benchmarks. The vehicle aerodynamic model was meshed and solved with the required boundary conditions as per the operating scenario specified.

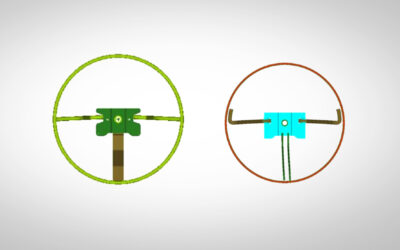

Simulation results were then interpreted for minimizing drag. Additionally the effect of various parameters like the change of curvature, splitters, etc. on the performance of the vehicle were analysed. Cumulative assessment of simulation results was done and specific design directions were shared with the client. Design was finalised incorporating the suggestions.