The final design was validated and verified through durability analysis and Proving Ground (PG) tests carried out at the client site.

Key Engineering Solutions

Solutions

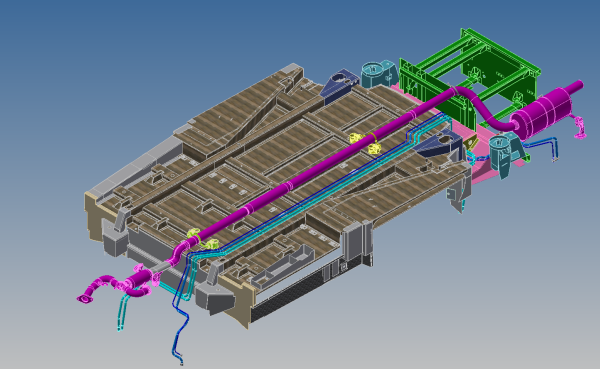

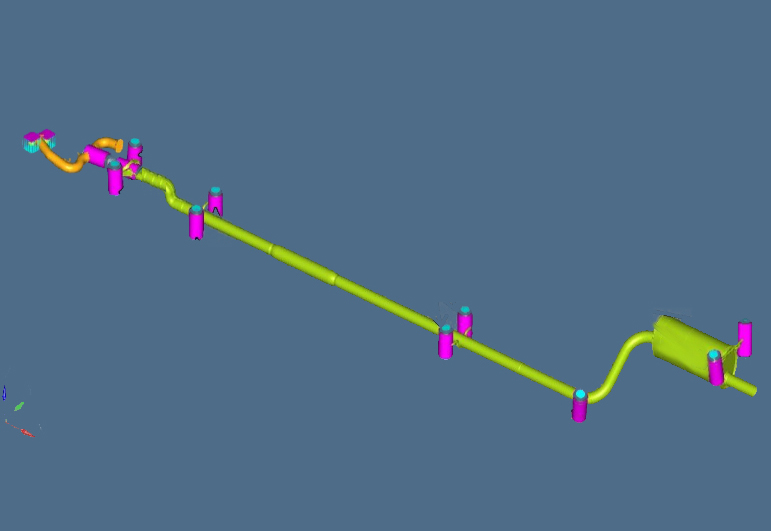

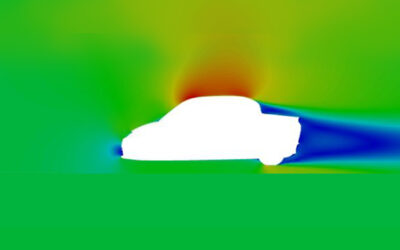

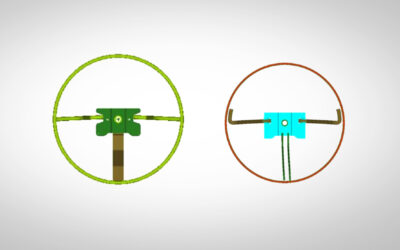

In the first stage, Timetooth performed detailed FE meshing of the exhaust system with appropriate isolator stiffness along different directions. Then, modal and linear static FE analyses were conducted on the meshed model. Natural frequencies and displacements/stresses were compared with acceptable values. Based on these values, the design was modified.

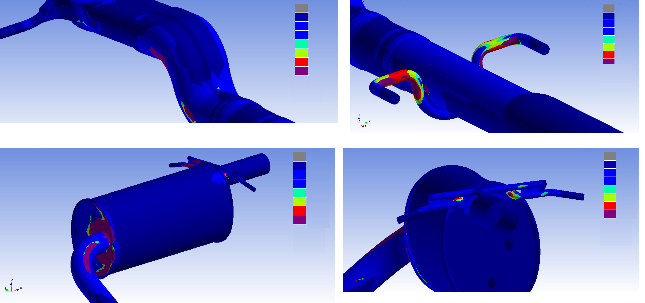

Next, RLDA data was used for fatigue life estimation. The measured body side data was converted to the exhaust side of the vehicle and mapped to the appropriate isolators. Leveraging the advanced simulation dynamic (MBD) analysis was carried out and the RLDA data was processed for durability analysis.

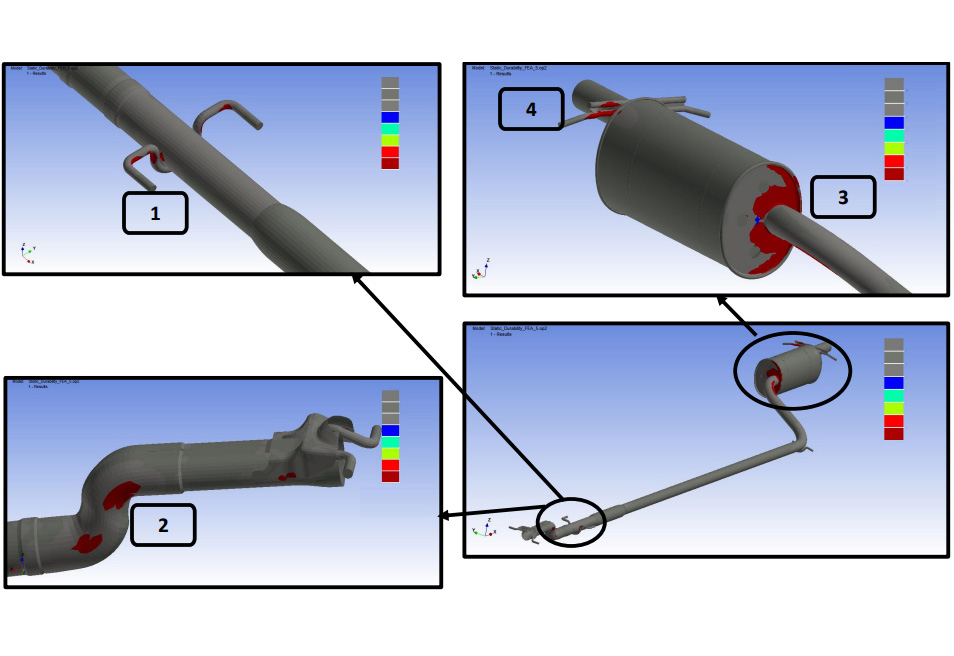

The durability analysis of the design was performed for the specified number of duty cycle repeats. By doing so, critical locations were identified from a durability perspective .

Based on the critical areas, design modifications were suggested. The resulting design was validated and verified through durability analysis and Proving Ground (PG) tests carried out at the client site.