Based on the simulation results, prototype manufacturing was carried out with controlled GD & T in conformance with the client’s rigorous quality standards.

Key Engineering Solutions

Solutions

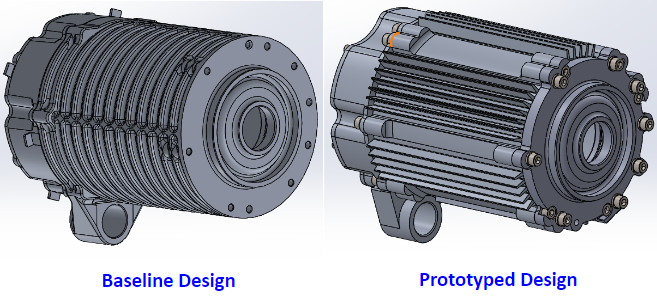

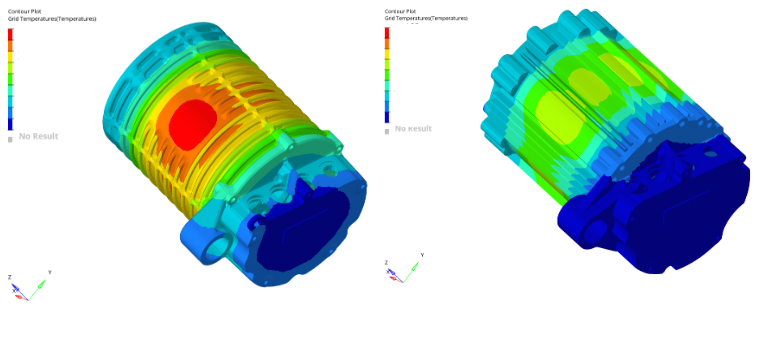

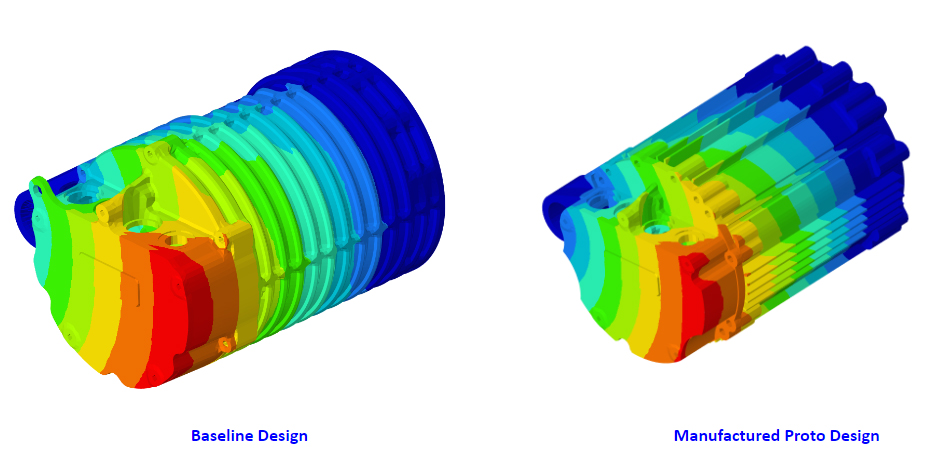

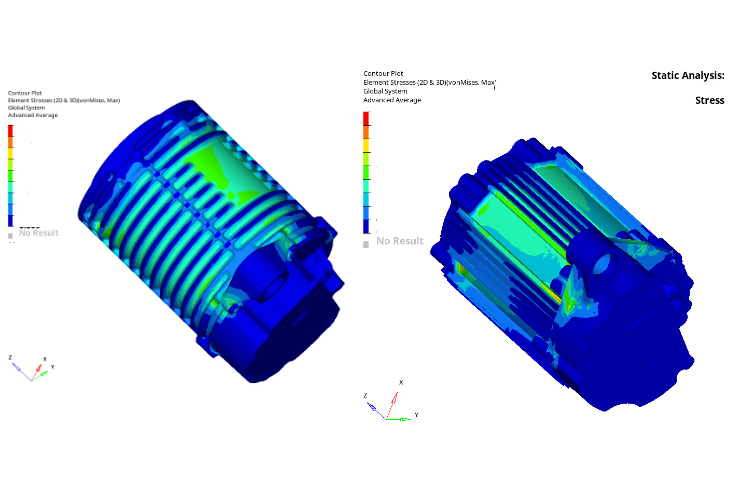

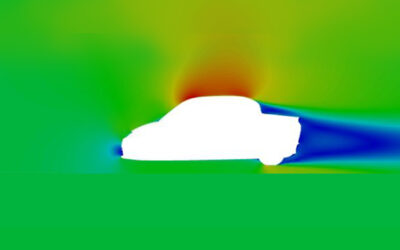

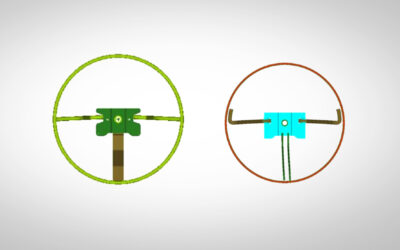

Timetooth commenced the project by developing design ideas modifying the baseline design. The client’s in-house acceptance criteria were studied, and various virtual validation tests were planned. Timetooth leveraged FE analysis to evaluate the designs. Modal Analysis was performed to determine the different mode shapes and their respective natural frequencies. Linear static analysis was conducted for analyzing the structural strength and rigidity. The effect of random vibration on structure was evaluated by PSD analysis. Subsequently thermal effect was analysed using CFD.

Based on the simulation results, prototype manufacturing was carried out with controlled GD & T in conformance with the client’s rigorous quality standards. Physical testing of the prototype was executed at the client site. The prototype cleared the structural acceptance criteria of the tests.