Correlation of the modal analysis results with the experimental results was done for the natural frequencies as well as the mode shapes.

Key Engineering Solutions

Solutions

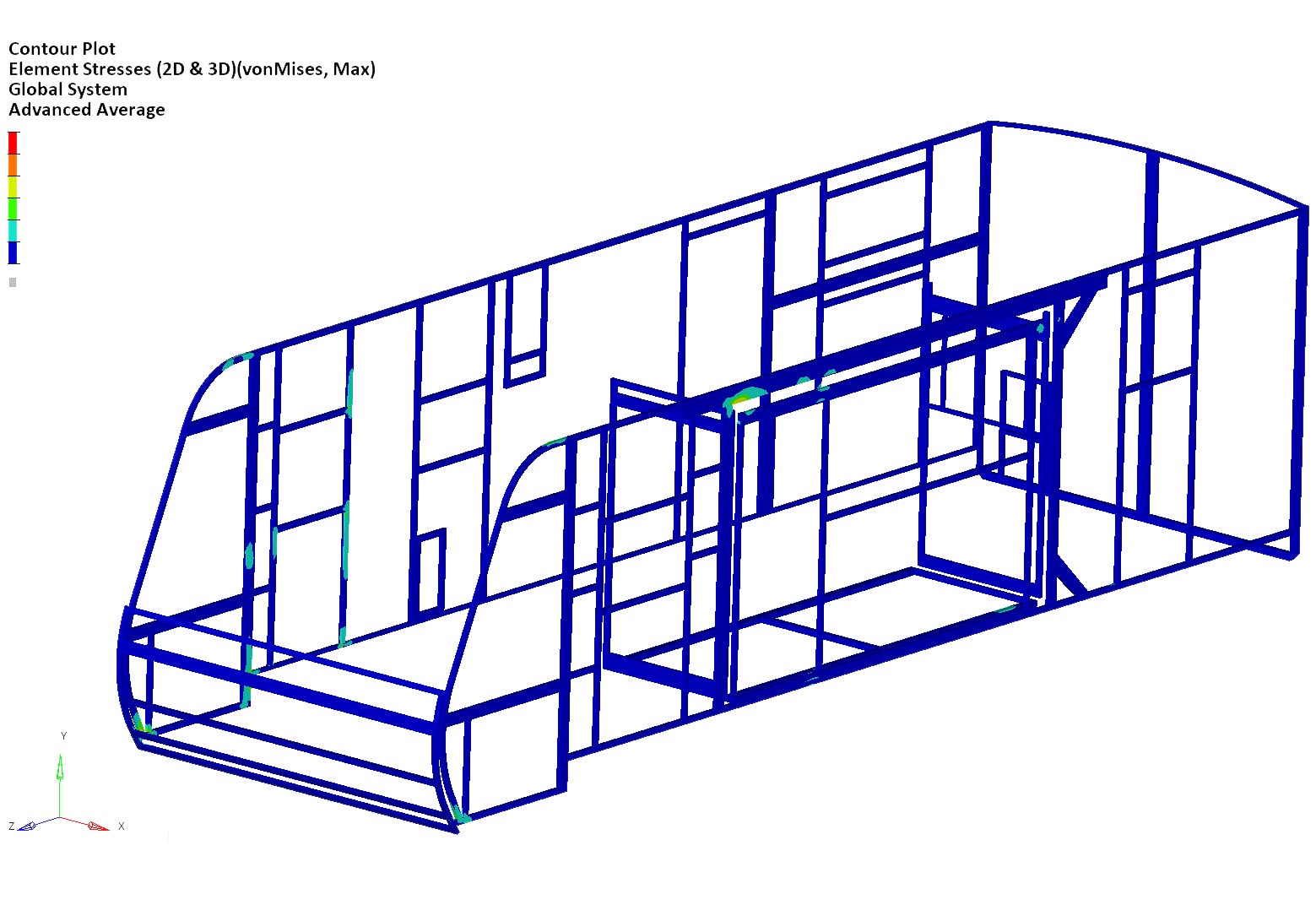

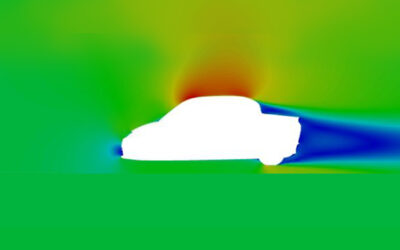

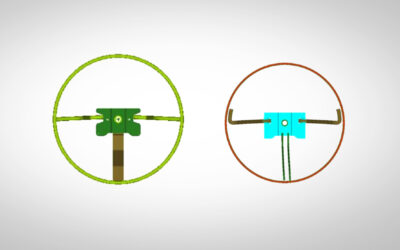

Timetooth initiated the project with study of the design model shared by the client and meshing of the vehicle as per the standards. Operational loading conditions were defined jointly by the Timetooth team with the RV OEM team for the analysis. Structural analysis was then carried out by applying road, snow and wind loads considering different parameters. Modal analysis of metallic structure, the wooden panels, and suspension was also performed. Simulation results were interpreted to understand the natural frequencies and validate the model. Further experimental modal studies were executed on the vehicle. Correlation of the modal analysis results with the experimental results was done for the natural frequencies as well as the mode shapes. As per the assessment design direction was suggested to the client for improvements in local/panel mode in future.