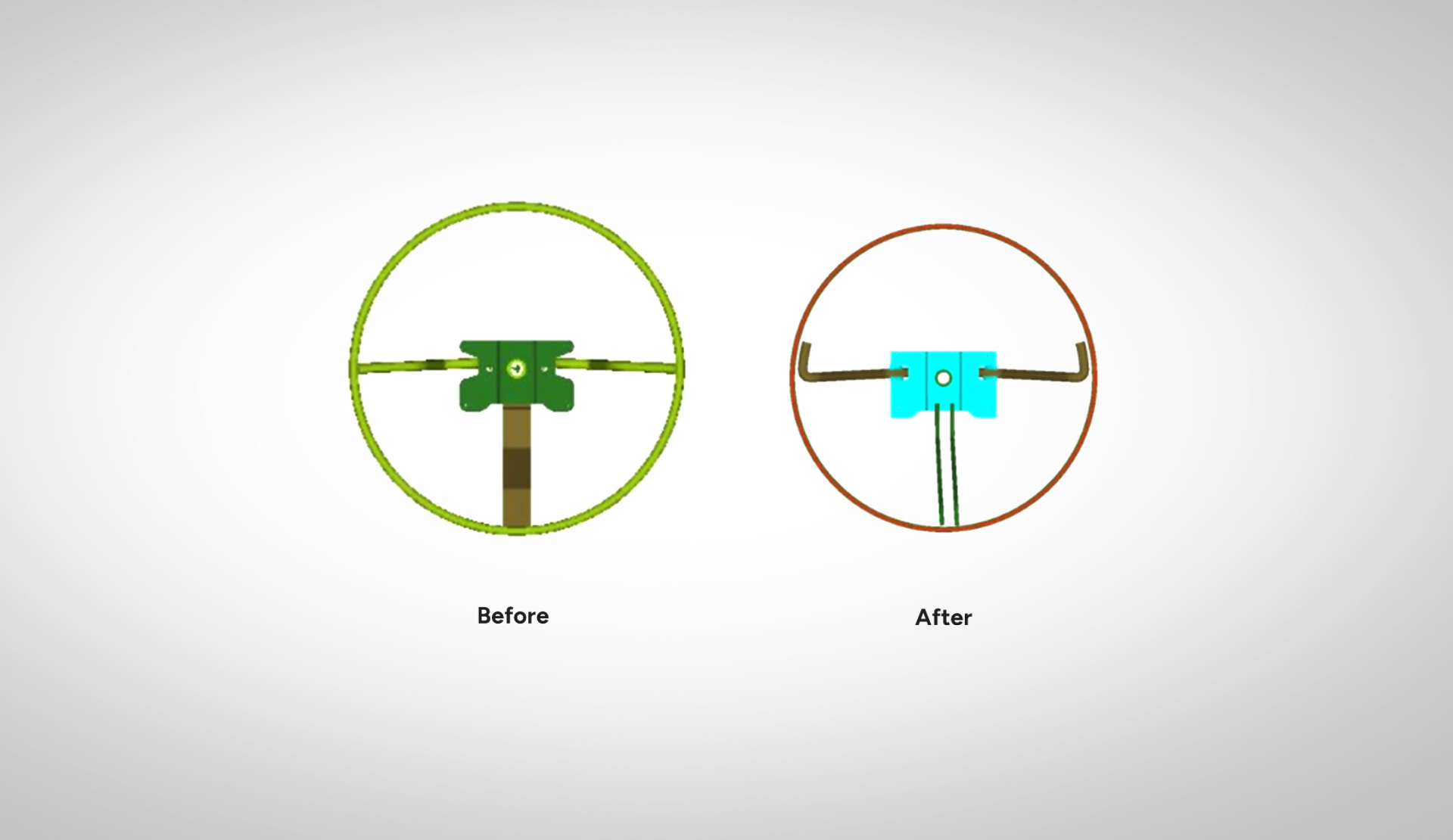

Since this early design innovation, custom cross-sections in steering wheel armatures has become an industry standard, found in almost 100% of passenger cars in production today.

Key Engineering Solutions

Solutions

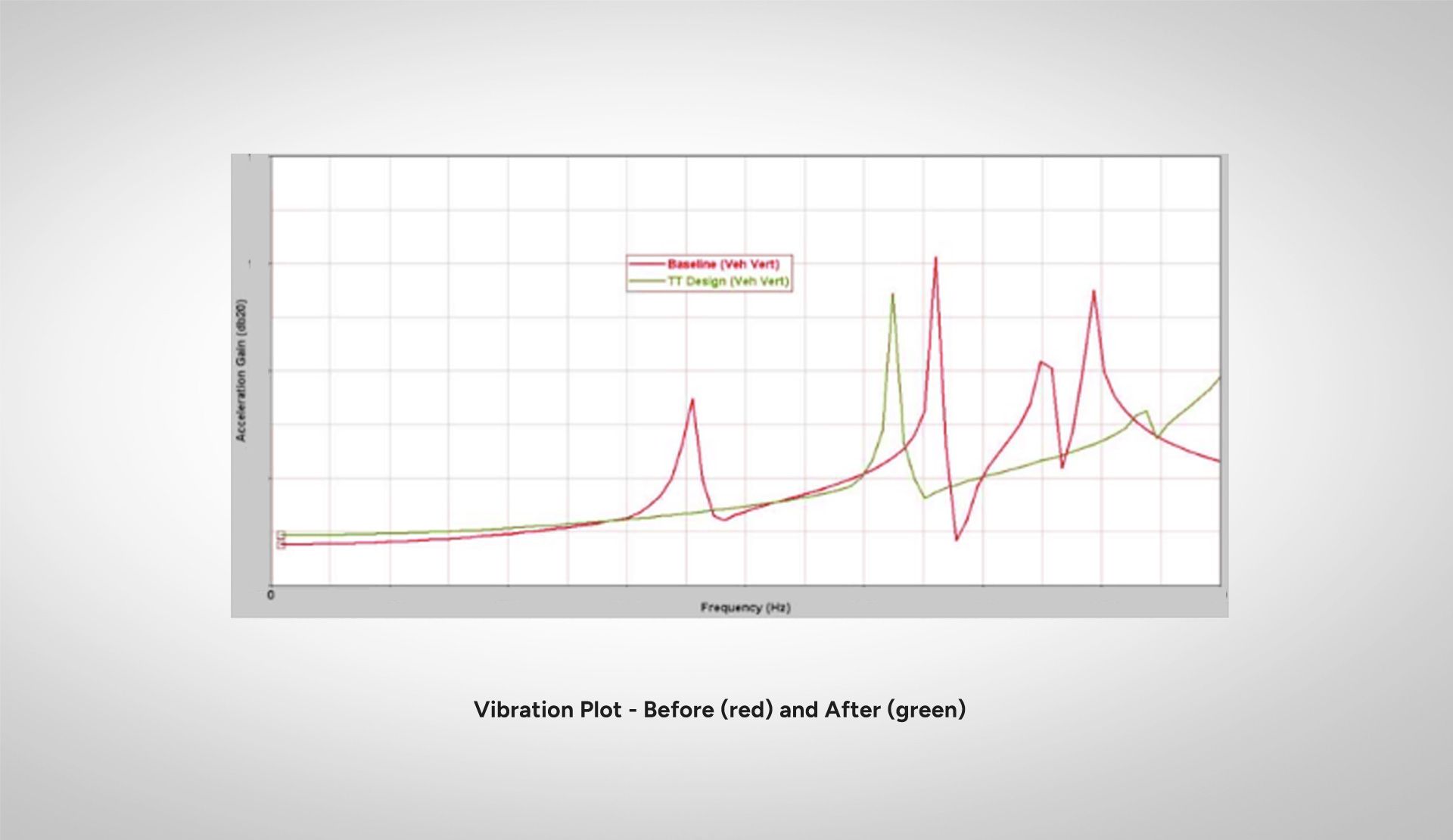

Simulation to the rescue – Timetooth engineers explored alternate designs for the “armature”, the metal frame embedded inside the plastic exterior of the steering wheel, while maintaining an unchanged external appearance. The optimal solution appeared: replace the traditional round cross-section of the armature with a custom-designed, figure of eight section. The final cross section not only reduced the vibration, there was a bonus: the final steering wheel was also lighter in weight.

Between 2009 to 2014 the concept of using a custom-designed cross-section for steering wheel armature was progressively adopted by other car manufacturers all over the world. It has become an industry standard, found in almost 100% of passenger cars in production today.

Today the old circular cross section is extremely rare if at all and used only in non-passenger car applications (fork lift trucks etc.).